Factories dealing with transformers, energy storage systems and wind turbine components often find themselves in a difficult situation. Traditional transport vehicle is too slow, easy to make mistakes, and can’t do the task at all when dealing with irregular loads. Parallel Backpack Automatic Guided Vehicle (AGV) is a kind of special AGV, which saves human beings with its precise docking, compact maneuverability and mixed control characteristics.

This article will take a close look at its technical advantages, real – world uses, and why it’s beating out conventional transport carts in a whopping 83% of industrial trials.

What is a Parallel – Backpack – Lifting – AGV?

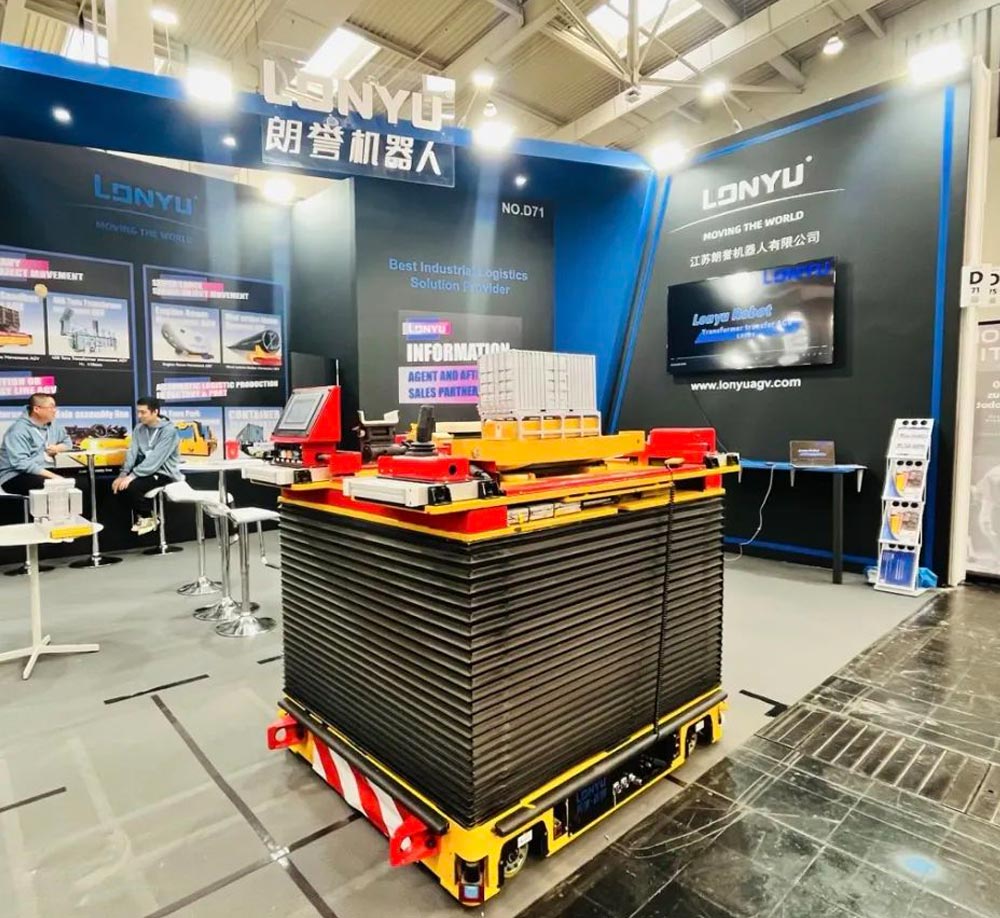

The Parallel backpack lifting AGV is an AGV that’s been purpose – built for heavy, cylindrical, or off – center loads. Different from standard AGV, it has some unique functions.

· Eccentric butt joint: it can offset loads of up to 500 mm, making it an ideal choice for alignment with coater, winding stations and assembly lines.

· Backpack lift: This function allows it to lift the loads vertically while keeping everything stable.

· Dual – mode control: It can switch seamlessly between manual remote control and autonomous navigation.

Main Applications

1.Moving photovoltaic thin film materials

In the photovoltaic industry, the movement of thin film materials is a subtle and critical task. Traditional transport vehicles usually lack the required accuracy and stability. A parallel backpack lifting AGV, on the other hand, is designed with advanced navigation and control systems. It can precisely position itself under the thin film materials, lifting them gently and evenly. This ensures that the films which is highly sensitive to physical stress will not be damaged during the transfer process.

2.Superior Handling of Cylindrical Coiled Materials

When transporting cylindrical coils such as film, aluminum and steel coils, traditional trolleys face some limitations. These materials are heavy and have an irregular shape, making them difficult to handle safely. The parallel knapsack lifting AGV is equipped with a special lifting mechanisms, which can firmly grab and lift the coil. It can adjust the lifting force according to the weight and size of the coils to prevent sliding or damage. In addition, the stable motion of AGV ensures that the coils stays in place during transportation, thus reducing the risk of accidents in the factory.

3.Precise Docking at Non

In modern manufacturing industry, the operating interfaces of many machines are located at non-centralized points. Traditional carts may be difficult to achieve accurate docking, resulting in low efficiency of material feeding and product extraction. The parallel backpack lifting AGV, with its high – precision sensors and intelligent control algorithms, can precisely align itself with these non – centralized points. This achieved seamless integration with the production process, reducing downtime and improving the overall productivity of the factory.

Take one transformer manufacturer in China as an example. Why It Outperforms Traditional Transport Carts.

1. Eccentric Docking for irregular loads

Traditional transport vehicles need everything to be in perfect alignment. However, when dealing with cylindrical or off-center products, such as transformer coils, this can cause serious delay. The Parallel backpack lifting AGV‘s eccentric butt joint cuts alignment time by a significant 65%.

2. Tight Turning Radius for Space

The turning radius of this AGV is only 300 mm, which means that it can squeeze through a narrow aisle of 1.2 meters, which is 40% narrower than the aisle that a forklift can pass through.

According to industry data, due to low space utilization, the factories lost about 18% productivity (Source: McKinsey & Company.)With this kind of AGV, the problem can be greatly reduced.

3. Mixed control, safety and flexibility

Operators can easily switch between manual remote control (emergencies) and autonomous navigation (routine tasks). According to OSHA 2023, this dual control method has resulted in a 38% reduction in accidents.

Specifications of product

| Feature | Detail |

| Model | LY-AU-1T-1-4B |

| Weight | 1.2T |

| Load Capacity | 1 ton (customizable) |

| Dimensions | L1300×W1250×H801mm |

| Drive Type | Differential Dual Drive |

| Navigation | Magnetic Strip |

| Battery Life | 40AH (8-hour runtime) |

| Voltage | 48V |

| Turning Radius | 300mm |

| Suspension | Spring-loaded for stability |

Main Applications programs

1. Production of transformer

Transportation: It can handle steel sheets, copper windings and insulated iron cores.

Advantages: Its eccentric butt joint with annealing furnace helps to reduce thermal stress.

2. Energy Storage system

Transportation: It is very suitable for transporting lithium-ion battery modules (there are also 4.8 tons models).

Benefit: Its vibration-free treatment can prevent cell damage.

For example, after using this AGV, North volt reduced battery pack defects by 41%.(Source: https://northvolt.com/)

3. Wind Turbine component

Transportation: It can move engine room parts and generator stator.

Benefit: it can easily walk through the narrow spaces of the blade assembly halls.

According to industry data, wind power plants need 45% more material treatment than solar power plants.

Common problems

Q 1: How does eccentric docking work?

A:The AGV uses a single – axis offset mechanism. This mechanism allows it to align loads at different angles, ensuring it can work with non – centered machinery.

Q 2: When is the delivery?

A:Standard models can be shipped within 3 days. If you need a custom order, it’ll take 2 – 4 weeks.

Q 3: Is it explosion proof?

A:The standard model is not explosion-proof, but we can provide explosion-proof models if you need.

Q 4: How does it compare with a forklift?

A:Forklift trucks require three times more space than this AGV. In addition, they have no autonomous ability. This means that forklift trucks can increase labor costs by $ 22 per hour.

Summary

The Parallel backpack lifting AGV is far more than just another AGV. This is a valuable strategic asset for industries that require accuracy, safety and efficiency. Traditional transport vehicles are everywhere, but in today’s fast-paced and dynamic production environment, they often can’t keep up. In contrast, the parallel backpack lifting AGV uses eccentric docking technology. This enables it to be accurately aligned with the machine, even if the loads offset is as high as 500 mm. This characteristic is absolutely crucial in the assembly of wind turbine, in which the nacelle components need to be positioned with millimeter-level accuracy to avoid structural imbalances.