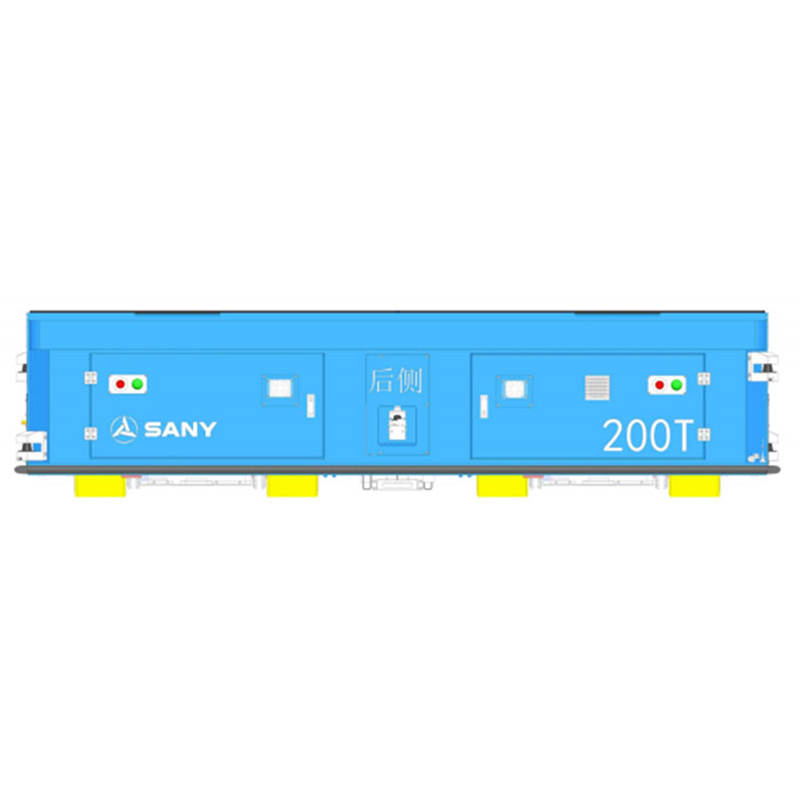

Indoor and outdoor handling of wind turbine main engine/drive system Automated guided vehicle system Heavy-duty AGV

Model :24111A

Rated load (T) :200

Weight (T) :30

Maximum vehicle dimensions (mm) :8210mm*3620mm*885mm

Lifting stroke (mm) :200mm

Gradeability (°) :≤5°

Operating environment: Indoor and outdoor

Number of drive wheels (pairs): Eight-wheel drive, sixteen-wheel

Operation mode: Forward, reverse, left and right

Drive motor type: Low-voltage servo motor + independent servo controller

Suspension type: Hydraulic suspension

Travel speed: 48m/min (no load), 36m/min (full load)

Battery type: Lithium iron phosphate battery, battery life: 3 hours (full load, empty)

Navigation accuracy (mm) ±10

Positioning accuracy (mm) ±10

Navigation method: Magnetic stripe

Control method: Automatic

Safety protection: Laser obstacle avoidance sensor + contact collision avoidance + audible and visual warning + emergency stop

Charging method: Manual charging

Braking distance (mm): ≤500mm (full load), ≤300mm (no load)

Protection level IP54

Applications: Indoor and outdoor transportation of wind turbine main engines and drive trains

Automatic Guided Vehicle

Automatic guided vehicle systems, also known as an AGV system, otherwise known as an automated guided vehicle,autonomous guided vehicles, or even automatic guided cart, is a system that follows a predestined path around a facility. An AGV automated guided vehicle is a motorized vehicle that carries a load through either an assembly,manufacturing, or warehousing facility. An AGV can take on any form a customer requires to best address their application needs.

1.Magnetic Strip Navigation

Similar to electromagnetic guidance, magnetic stripe navigation uses magnetic stripe tape on the road surface instead of buried metal wires, achieving guidance through magnetic induction signals. This method offers greater flexibility, making it easier to change or expand the route, and the tape is simple to lay. However, this guidance method is susceptible to interference from surrounding metal objects and mechanical damage, making guidance reliability significantly affected by external factors.

2.Laser SLAM Navigation

Laser guidance involves installing precisely positioned laser reflectors around the AGV’s path. The AGV uses a laser scanner to emit laser beams and simultaneously collects the laser beams reflected by the reflectors to determine its current position and heading. AGV guidance is achieved through continuous triangulation. The biggest advantages of this technology are precise AGV positioning; no additional ground positioning equipment is required; and the driving path is flexible and adaptable to various field environments. It is currently the preferred advanced guidance method by many international AGV manufacturers. However, its disadvantages include high manufacturing costs, relatively stringent environmental requirements (such as ambient light, surface conditions, and visibility), and its unsuitability for outdoor use (especially due to rain, snow, and fog).

3.GNSS-GPS/Beidou Navigation.

4.Others—Ink ribbon, vision, and QR code.

The AGV drive system includes: wheels, servo motors, planetary reducers, chains, housings, slewing bearings, hydraulic cylinders/springs, etc.

Types of Automated Guided Vehicles

There are many different types of agv vehicles in use today.

Energy storage industry container applications:

AGVs lurk beneath tooling stirrups, automatically raising and lowering to lift products. Within the production line, they can shuttle back and forth, transferring stirrup products and enabling flexible container production. Currently, they are being used by CIMC Energy, Geely Zeekr, and CATL.

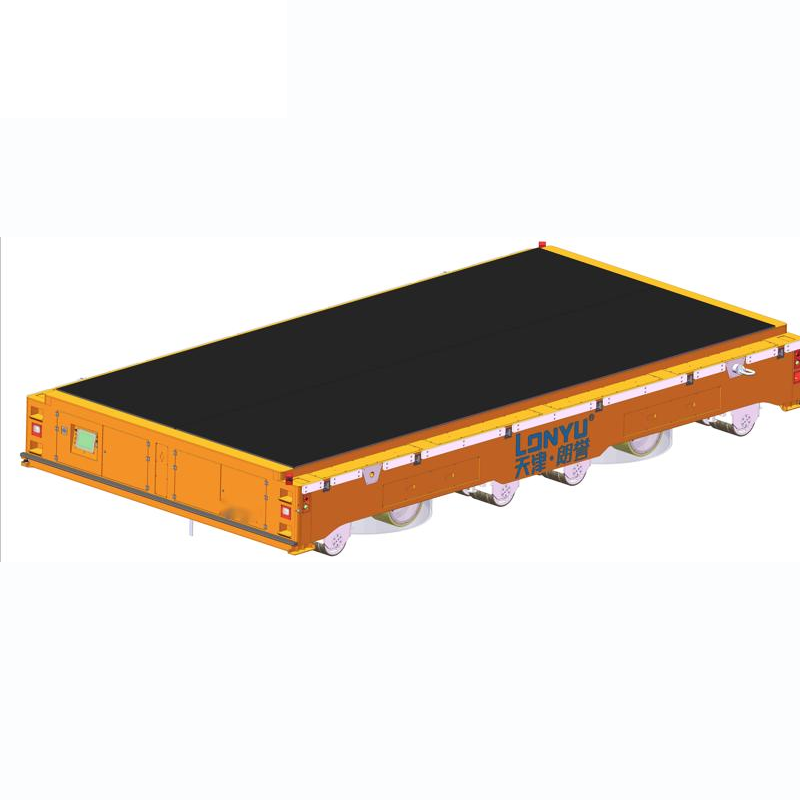

Transformer Ultra-Thin, Ultra-Heavy-Duty AGVs:

- Multi-motor coordinated omnidirectional drive

- Multi-point hydraulic suspension and leveling system

- Multi-sensor fusion navigation

- Adaptability to diverse environments

- Multi-vehicle linkage technology

- Ultra-Thin Omnidirectional AGV (410mm)

Using AGVs as the primary vehicle for building

modern, flexible production lines, the AGV system automates the production process and meets production

capacity

requirements.

various sensor types to achieve full 360-degree coverage. The sensor fields of at least two sensors overlap

to

achieve redundancy.Easy to achieve 360-degree laser point cloud coverageSmall 3D blind spots for close-range obstacle detection

engineering)① Build a modern, flexible production line using AGVs as the primary vehicle. Automated handling within the

production process is achieved through the AGV system, meeting production capacity requirements.② Design optimal assembly automation tooling based on assembly process requirements to ensure mixed-line

production of multiple vehicle models.

related products

Product categories

Tags