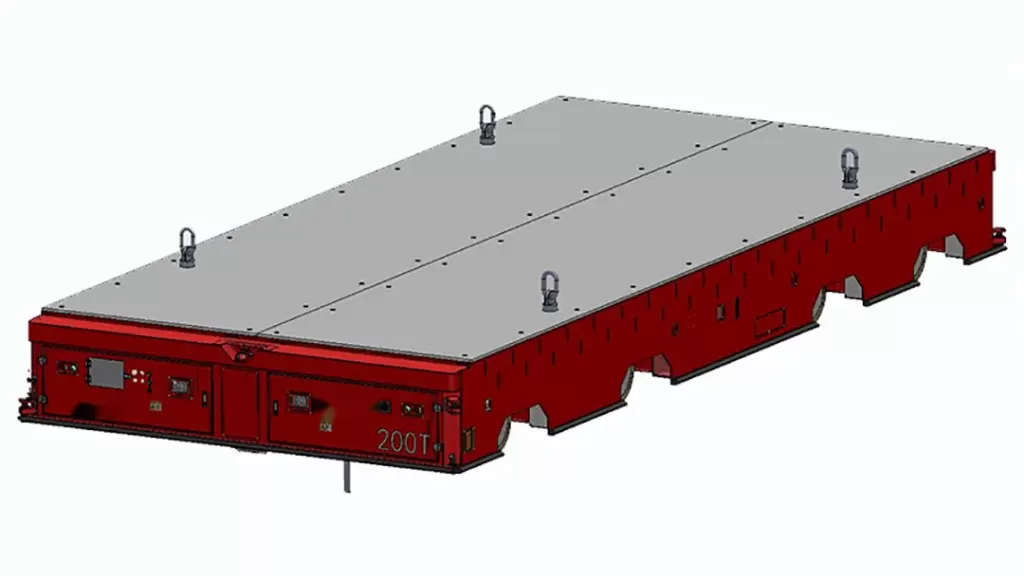

In the heavy load transformer industry, handling large-scale equipment-usually hundreds of tons-has long been a major challenge in logistics. Traditional manual/semi-automatic processing is slow and labor intensive, and there is a risks of damaging expensive equipment. This is where the 200t Heavy AGV Backpack Gearbox (model: LY-1-200 T-816-A) comes in: the special automated guided vehicle (AGV) parts designed for heavy-duty transformer transportation. This AGV backpack gearbox is specially designed for high capacity, high precision and high durability, which changes the way manufacturers, warehouses and field processing equipment are installed, ensuring efficiency, safety and reliability. This guide breaks down what it is, its advantages for the sector, key specs, and real-world uses—highlighting its indispensability for modern operations.

What Is the 200 ton Heavy duty AGV backpack transmission box?

Its core is a high-capacity, durable automatic guided vehicle accessory, which is designed to “carry” and manipulate ultra-heavy load, mainly heavy-load transformer units. Unlike standard AGV with loads of more than 50 tons, this backpack transmission box is tailored for the extreme weight of this equipment, and the automated guided vehicle systems is integrated to realize accurate movement.

“backpack” refers to its design: it is attached to the AGV like a backpack, evenly distributing weight to avoid stress points. Its core function bridges automated mobility and heavy-load handling—critical in the heavy load transformer industry, where small movement errors cause costly damage or delays. Whether a unit is transferred from production to testing, storage or outdoor installation, this AGV backpack transmission box uses automated guided vehicle technology to reduce manual work and simplify workflow.

Unique Advantages for Heavy Load Transformer Applications

What makes this 200 ton AGV backpack gearbox different from others? Its advantages are aimed at the challenges of the industry, making it a game changer.

1. Ultra high load capacity

Its rated load of 200,000 kg (200 tons) is equivalent to the weight of many industrial heavy load transformers. The maximum weight of the traditional AGVs forklift is 50-100 tons, which forces the teams to use inflexible cranes or dangerous manual rigging to carry larger equipment. This box eliminates this gap: it safely carries even the heaviest models, maintaining its integrity. For manufacturers, an automatic guided vehicle with such a box can replace a variety of tools.

2. Steady weight distribution

Heavy load transformer units are precision-engineered; Uneven weight damages internal components. Automated guided vehicle backpack gearbox adopts double suspension (hydraulic+passive), which distributes the weight across 16 wheels (8-wheel drive) to avoid pressure points on the shell. Even on the uneven factory floors, suspension system can absorb the vibration and keep the equipment stable. For example, transporting one to test can avoid the vibration of internal winding dislocation-protect expensive gear.

3. Precision Navigation

Heavy load transformer installation/testing needs millimeter accuracy. This box uses magnetic stripe navigation with ± 3 mm inching accuracy—far better than manual methods or standard AGVs (± 10 mm). Aligning a unit with test terminals or tight warehouse shelf eliminates the risk of rework and collision. Moving a 200 ton device into the test cabin: the automatic navigation vehicle slides into place with the accuracy of 3 mm without manual adjustments.

4. All-Environment Durability

Heavy load transformer operations aren’t indoor-only—many need outdoor transport (e.g., warehouse to substation). The box can be used indoors/outdoors, and the protection level is IP 44/IP 65 (IP 65 = dustproof and low-pressure waterproof). For installer, an automatic guided vehicle system handles production, installation and cutting tool requirements.

5. Integrated security

Safety is very important for heavy duty transformer. This kind of box has multi-layer safety: laser obstacle avoidance, contact collision avoidance, sound/light warning and emergency stop. These protect workers and prevent unit from being damaged-a collision will cost tens of thousands of dollars in repairs costs. For warehouses, the system reduces accidents and meets safety standards.

Main application Scenarios: heavy-duty transformer industry

This automated guided vehicle knapsack gearbox serves the whole life cycle of equipment-from production to maintenance.

1. Productive transportation

In the factory, units goes through several stages: core assembly, winding, testing and packing. Traditional methods, such as bridge crane, need a lot of settings and have a small spaces. The automated guided vehicle with this box picks up some units and moves them to winding/testing (3 mm precision) without manual operation. Its 8 wheel drive can handle floor conversion; Thin is suitable for the unit base. Compared with cranes, this reduces the production time by 30%.

2. Storage in warehouse

The storage units is challenging: it is too heavy for standard racks, and there is a risk of damage by manual movement. This box can lift 200 tons of equipment (200 mm stroke) to a heavy frame. Magnetic navigation ensures perfect alignment. Retrieving the equipment for transportation is very quick, and there is no need to arrange a crane. This reduced the labor cost of the warehouse by 25% and accelerated the customer orders.

3. Installation Transport

Installing equipment in outdoor substations usually needs to be transported from truck to site, which is too far for crane. The IP 65-rated box handles outdoor transport, climbing ≤ 5 ° ramps easily. Precise navigation accurately places units on the basis. This eliminates temporary crane and reduces the installation time and safety risk by 25%.

Why It’s Indispensable for Heavy Load Transformer Operations

Efficiency, safety, and precision are non-negotiable in the sector—and this AGV backpack transmission box delivers on all three by leveraging automated guided vehicle technology to solve longstanding handling challenges. Different from the traditional methods:

It eliminates manual labor risks: reducing transport accidents by 40% vs. cranes or forklifts.

It reduces the delay of workflow: because the automatic guided vehicle system runs around the clock and there will be no fatigue.

It protects expensive equipment: stable suspension and accurate navigation reduce the risk of component dislocation by 90%.

Conclusion

200 ton heavy AGV backpack gearbox (model: LY-1-200T-816 A) is used to transform the heavy load transformer industry. It combines automatic guided vehicle technology with ultra-high load capacity, accurate navigation and all-weather durability, and solves key handling challenges for manufacturers, warehouses and installers. Its unique advantages-from uniform weight distribution to comprehensive safety-are tailored according to the needs of the industry, ensuring the efficient transportation of key and expensive equipment.

If you are looking for simplifying workflow, reducing risk and improving productivity in the industry, this product is your ideal choice. It is not only an automatic guided vehicle accessory, but also a key contributing factor for modern efficient operations.