In industrial automation, efficient, safe, flexible heavy-load transportation is critical. Industries with huge equipment (especially energy storage cabinets) needs reliable solutions. The 40 Ton omnidirectional lifting AGV stands out as a high-performance heavy-duty agv, solving heavy-load challenges. This article explores what this automated guided vehicle is, its advantages, specs, key role in energy storage, and other use cases.

What is a 40 Ton-omnidirectional-lifting-AGV?

First of all, Automatic Guided Vehicle (AGV). Automatic guided vehicle system (also known as AGV system, automatic guided vehicles or automated guided vehicle) is a motorized solution that follows the preset path in facilities (manufacturing plants, warehouses, logistics centers). Different from the manual methods, it runs with minimal human intervention, transports goods through assembly/ manufacturing/ warehousing, and can be customized.

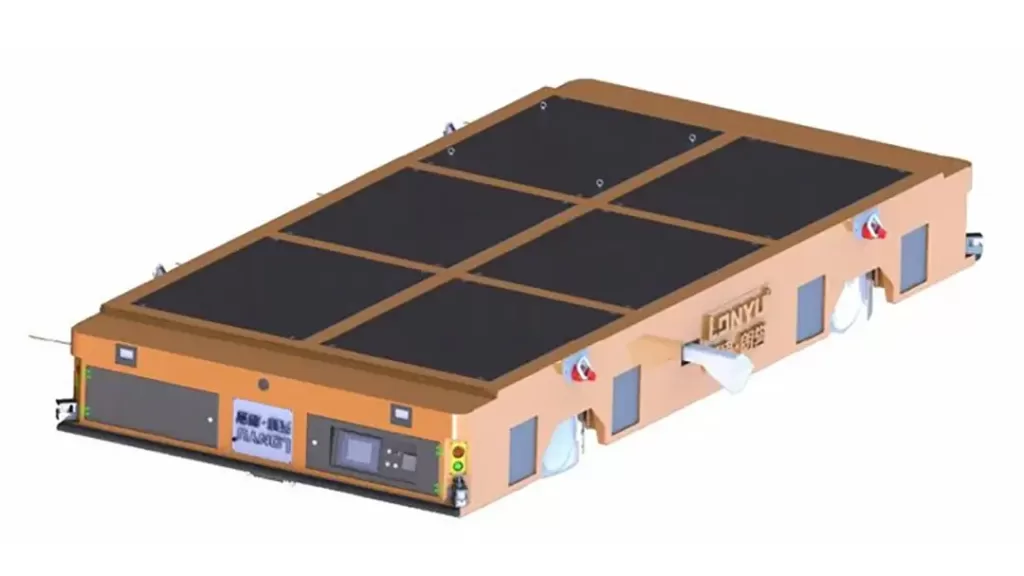

The 40 Ton omnidirectional lifting AGV is a specialized heavy duty agv handling up to 40 tons. Its main feature are: completely flat surface, enhancing the compatibility with energy storage cabinets. It can be seamlessly integrated with heavy-duty racks to ensure smooth transportation and zero inclination (the key to avoiding damage). Omni-directional mobile navigation in narrow spaces improves the versatility of height adjustment.

Unique Advantages of the 40 Ton omnidirectional lifting AGV

As a cutting-edge automated guided vehicle, it provides outstanding advantages for energy storage.

1. Improvement of efficiency

This heavy duty agv runs 24/7—game-changing for the sector’s non-stop production. It reduces the dependence on labor, and eliminates fatigue/error delay. Automated transportation shortens cycles: for example, semi-finished cabinets are seamlessly moved from welding to assembly to storage, thus improving productivity.

2. Enhance security

Manual heavy-load operation risks errors/injuries. This automatic guided vehicle has advanced sensor/navigation system, which can detect obstacles, avoid collisions and stabilize loads. The heavy duty agv‘s zero-tilting design cuts displacement, protecting workers and cabinets.

3. Flexibility and scalability

Industrial environment is constantly changing, and this kind of AGV is easy to adapt. As an automated guided vehicle, the route is adjusted by software (without facility module). A storage cabinet factory expanding can reprogram it quickly. It’s scalable: multiple heavy duty agv units can handle higher loads.

4. Optimization of cost

It cuts costs from three aspects: reducing manpower (instead of labor, no overtime); Reduced maintenance (simpler than crane/forklift); Save space (compact, omni-directional motion uses narrow areas) automated guided vehicles maximize the use of energy storage business resources.

5. Data driven Operations

In intelligent manufacturing, this automated guided vehicle sends real-time data (position, speed, load, battery and task status) to a central system. Managers monitor cabinet movement to make quick decisions (e.g. Rerouting for bottlenecks). Data analysis has optimized the processes of path redesign.

Product Specifications of the 40 Ton-omnidirectional-lifting-AGV

1. Loading Capacity

This heavy agv can handle up to 40 tons of goods and is an ideal choice for energy storage cabinets (industrial use is 10-35 tons). For heavy tasks, it is better than the standard AGV (less than 10 tons).

2. Omni-directional motion

Different from the traditional AGV, it can move freely (forward/backward/left/right/360 rotation), and there is not much turning space. It is very important for high-density energy storage facilities: it can effectively pass through gaps/obstacles.

3. Lift Function

A high-performance mechanism can adjust the plane height (100 mm to 1500 mm, which can be customized) Essential for high-rack storage: the automated guided vehicle loads/unloads without cranes.

4. Planar surface design

It is made of high strength steel and will not deform under heavy loads. Perfect alignment with racks (no blockage/inclination) protects the bottom of the cabinet.

5. Navigational control system

Supports laser (5 mm accuracy for open spaces), magnetic tape (for handling pollutants) and vision-based navigation (for reflector-free/magnetic tape-free areas). The central system of automated guided vehicle supports remote monitoring, task assignment and fault diagnosis (minimizing downtime).

Key Application: 40 Ton-omnidirectional-lifting-AGV in the Energy Storage Cabinet Industry

The energy storage industry is developing rapidly, but it is very difficult to transport heavy cabinet. Key technology of heavy agv transformation.

Pipeline transport

There are several stages in manufacturing (frame manufacturing to component installation). Traditional methods (crane, forklift) will cause bottlenecks. The 40 Ton omnidirectional lifting AGV—as an automated guided vehicle—is summoned via central control, adjusts to production table height, moves cabinets to next stages, and navigate equipment/workers, speeding up production.

Storage and retrieval in warehouse

Cabinets stored in high-density racks require a heavy-duty and height-adjustable solution. AGV transports the finished cabinets to the shelves, adjusts height through the lifting function of automated guided vehicles, and accurately places them. Real-time tracking simplifies inventory and reduces ordering time.

On site installation support

It is very difficult to install in the field (solar power plants, wind power plant) (space is limited). The crane is expensive/inflexible. The heavy agv transports cabinets to sites through a narrow path, which matches the height of the installation base. For large-scale solar energy projects, it can run continuously and speed up installation.

Maintenance and Replacement

Cabinets need to be maintained/replaced, which makes transportation difficult. The AGV moves cabinets to maintenance areas (secure even disassembled) and returns them post-repair. It exchanges old/new cabinets, and the safety features of automatic guided vehicles protect workers/equipment.

Conclusion

The 40 ton omni-directional lifting agv is a revolutionary heavy duty AGV, which has changed the heavy-haul transportation, especially in energy storage. As an automatic guided vehicle, it combines efficiency, safety, flexibility, cost effectiveness and data-driven operation.

Its specifications (capacity of 40 tons, omni-directional movement, lifting, plane and advanced navigation) make it perfect choice for energy storage-simplifying production, storage, installation and maintenance.

In addition to energy storage, it also serves manufacturing, logistics, special environment, new energy and flexible production lines. With the development of automation, this kind of automated guided vehicle becomes more and more important. For high-load enterprises, investing in it can bring long-term productivity, security and cost savings.