In heavy industry manufacturing, transporting heavy duty transformers has been a challenge for a long time. These large, power transmission-critical units often weigh hundreds of tons, making movement within factories, between workshops, or to installation sites difficult. Traditional methods such as cranes and forklifts are limited by space/flexibility, so it is difficult to ensure the stability/safety of heavy duty transformer during transportation. However, the 600-ton heavy-duty automated guided vehicle (AGV) has completely changed this point, providing a reliable and efficient solution for heavy-duty transformer transport.

What is the 600 ton Heavy duty Automated Guided Vehicle (AGV)?

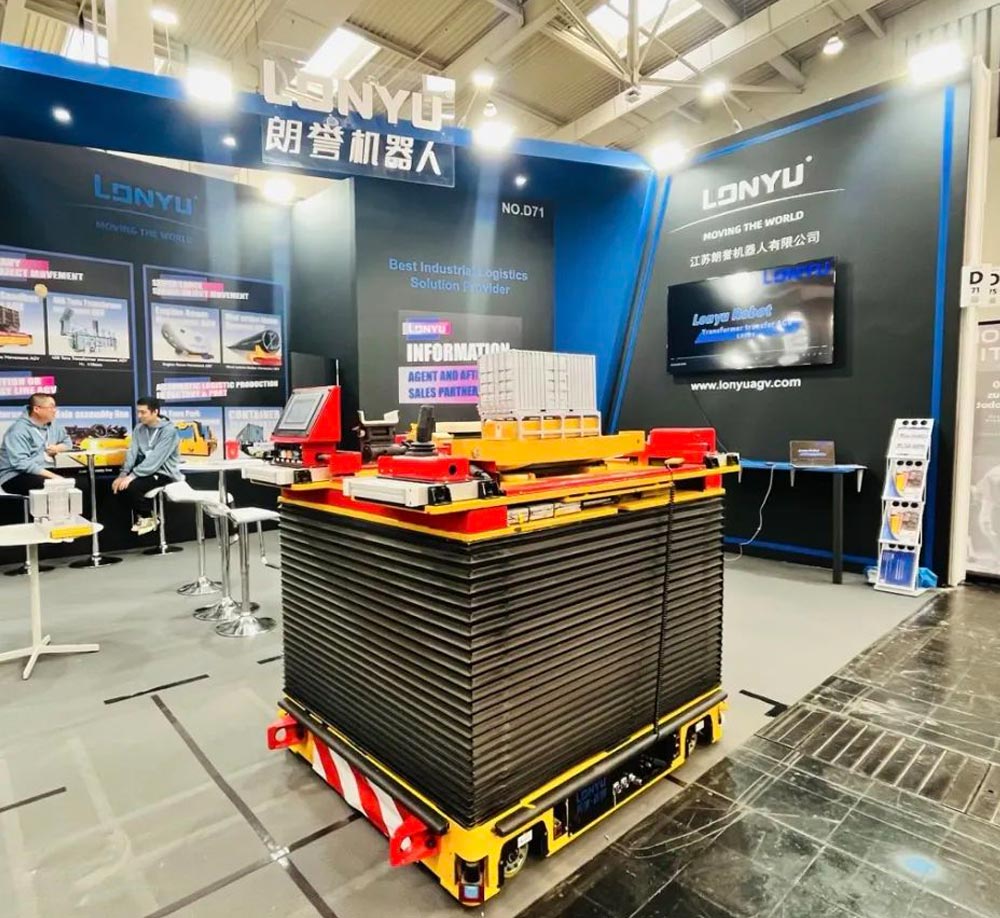

600 ton heavy automated guided vehicle (AGV) (Model: LY-1-450 (600) T-416 A) is a special automatic loading and unloading equipment for super-heavy loads, focusing on solving the transportation challenges of heavy transformers. Unlike light/medium load AGV, this type of AGV can bear the weight of heavy transformer, ensuring smooth and accurate movement in various environments.

At its core, this automated guided vehicle integrates advanced mechanical design, intelligent controls and powerful safety functions, which is suitable for heavy industry. It minimizes manual operation (through wireless remote control/navigation), reducing human error and improves the transportation efficiency of heavy duty transformer. It is a high-performance special tool for transferring heavy transformer from production to testing, or from warehouse to transportation.

Unique Advantages of the 600 ton Heavy duty AGV for Heavy duty Transformer Transportation

For heavy duty transformer transportation, 600 ton heavy duty automated guided vehicle (AGV) is superior to the traditional methods in key advantages.

1. Excellent load bearing capacity

Its rated load of 600,000 kg matches the weight of large heavy duty transformer, and even the heaviest equipment can be easily loaded without compromising its stability. Unlike cranes with fixed rails and limited movement range, this automated guided vehicle moves freely, ideal for transporting heavy duty transformers between workshops or outdoor yards.

2. Flexible mobile mode

It adopts differential drive and four-wheel drive (16 wheels), and has unparalleled flexibility. Under the conditions of no-load/full load, it can realize straight forward/backward driving, straight left/right driving, in-situ rotation and plane turn. This is very important for the transportation of heavy-duty transformers-the equipment usually needs to be moved in a narrow spaces (narrow workshop aisles) or accurately positioned (aligning with test equipment/container) Its in-situ rotation can adjust the direction of heavy transformer without large radii, saving space/time.

3. stable and reliable Suspension system

Double suspension (hydraulic+passive) ensures uniform wheel stress, even when heavy duty transformer are used on uneven roads. For heavy duty transformers sensitive to vibration, the system can minimize transportation impact, protecting internal components and maintain equipment quality.

4. All-Weather and all-environment adaptability

Designed for indoor/outdoor use (IP 44/IP 65 protection), it withstands dust, rain, and harsh conditions—ideal for moving heavy duty transformers from workshops to outdoor storage or installation sites. It operates normally in dry factories or rainy yards, ensuring uninterrupted heavy duty transformer transport.

5. Comprehensive security functions

Laser obstacle avoidance, contact and collision avoidance, sound/light warning and emergency braking are preferred. Laser sensors detects obstacles in real time; Contact equipment increases protection; Warn the warnings personnel; Emergency stop can stop immediately. These features minimize heavy duty transformer transport accidents.

Main application scenarios of transformer industry

The 600 ton Heavy duty automated guided vehicle (AGV) is designed for the transformer industry, aligning with heavy-duty transformer production, testing, storage, and transport.

1. In-Plant transportation during production

Heavy-duty transformers need to be moved between production stations (winding of coils → assembly of iron cores → final assembly) Traditional tools such as bridge crane have fixed tracks and can not reach all corners of the workshop, resulting in low efficiency. The flexibility of this AGV enables it to transport heavy-duty transformers directly to stations, and even to rotate in situ to align with equipment, thus reducing the adjustment time/labor.

2. Transport for testing

After production, heavy duty transformers has been tested (insulation resistance, partial discharge, load) These tests are usually carried out in a special laboratory in the factory. The stable suspension and precision of AGV ensure vibration-free transportation to the laboratory. It can also move equipment between test stations, improving efficiency.

3. Warehouse storage/retrieval

After the test, heavy duty transformers will be kept in storage before shipment. AGV transports them to warehouse locations, even narrow aisles, and tightly places units without damage. When shipping, it quickly retrieves heavy-duty transformers to docks, reducing storage/retrieval time.

4. Outdoor transport to shipping/installation sites

When ready, heavy duty transformers are moved from warehouses to trucks or substations. The indoor/outdoor function (IP 44/IP 65) of AGV can handle this situation and transport the units to docks and align it with the flat. For nearby sites, it is delivered directly, reducing the risk of transmission and damage.

5. Support for on-site installation

In substations, heavy duty transformers needs accurate positioning. In-situ rotation of AGV and precise adjustment of unit position —— for example. G align the bolt holes with the anchor bolts-reduce the labor force on site and ensure the smooth installation.

Conclusion: Why This AGV is Essential for Heavy-duty Transformer Operations

In the transformer industry, heavy duty transformer transportation affects production efficiency, quality and safety. The 600 ton heavy duty automated guided vehicle (AGV) has solved the key challenges with its load-bearing capacity, flexibility, stable suspension, all-environment adaptability and safety.

Its specs—600,000 kg load, four-wheel drive (16 wheels), IP 44/IP 65 protection—are tailored for heavy duty transformer transport. It reliably serves for production, testing, storage, transportation and installation.

For transformer enterprises, investing in this kind of automated guided vehicle can improve the transportation efficiency of heavy-duty transformers, reduce the risk of damage and ensure the safety. With the increasing demand for large-scale heavy duty transformers and the increasingly strict efficiency/safety standards, this AGV will change the market competitiveness.