In today’s industrial automation environment, efficiency and adaptability are the key to maintaining competitiveness. Automatic guided vehicle (AGVS) with natural navigation has become a key tool, which has changed material handling in manufacturing and logistics industries. This article discusses what these innovative AGVS are, their main advantages and applications.

What Are Natural Navigation Automated Guided Vehicles?

Natural Navigation Automated Guided Vehicles, commonly referred to as AGVS, are self-operating transport vehicles designed to move goods in industrial settings without human intervention. Different from the traditional AGV, the traditional AGV depends on fixed paths, such as wires or lasers. These natural navigation systems provide greater flexibility while maintaining accuracy.

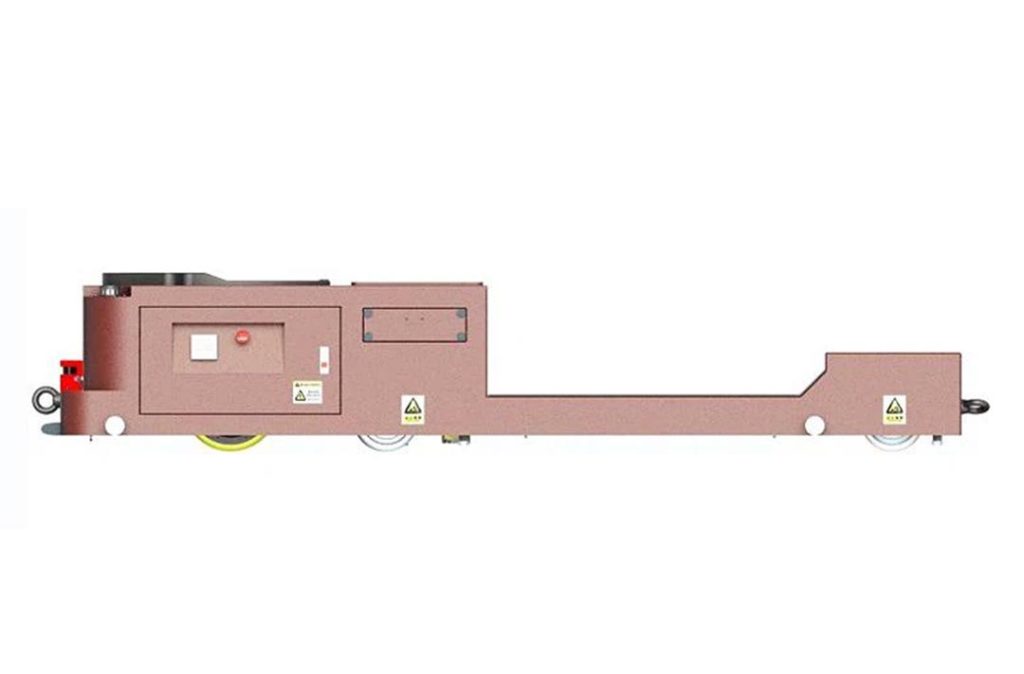

LY-AK-20 T-1-4 B model embodies this technology. Using magnetic stripe to navigate, it follows predefined routes and adapts to small environmental changes-very suitable for dynamic workplaces. As advanced AGVS, they simplify the transportation of materials through solid structure and intelligent controls, making them very important in modern industrial operations.

Key Advantages of Natural Navigation Automated Guided Vehicles

1. High load performance

LY-AK-20 T-1-4 B stands out with its 20 T load capacity, supported by two 10 t super drives-very suitable for transporting large construction machinery parts. Its tubesheet frame and spring suspension ensure durability, handling shocks to protect both the vehicle and cargo in harsh industrial conditions.

2. Flexible navigation

Magnetic stripe technology allows simple route modifications and eliminates the change of expensive infrastructure. With a turning radius of 2061 mm and four stable casters, this AGV can maneuver smoothly in narrow spaces, reducing the bottlenecks in busy facilities. This adaptability makes AGVS an indispensable part of the developing production lines.

3. Various operating modes

LY-AK-20 T-1-4 B provides manual remote control and automatic operation, with flexible operation. Automatic mode follows a pre-programmed route to maintain consistent efficiency, while manual control handles unexpected situations-ensuring uninterrupted operations. This duality is the sign of effective natural navigation to automatically guide vehicles.

4.a reliable supply chain support.

Yu Long Robot’s strong global supplier network ensures high-quality parts and shorter production cycles for its AGVS. Flexible delivery options from rapid transportation to customized schedules further enhance the value of these self-driving cars with natural navigation to meet various industrial demands.

Primary Applications

1.the construction machinery assembly.

This kind of AGV is good at moving heavy components between workstations in excavator production. Its 20 t capacity and compact size (L1800*W1300*H600mm) fit seamlessly into crowded assembly lines, accelerating production by reducing manual handling errors.

2, general production and transportation.

This AGV is an ideal choice for horizontal transport between manufacturing stages. It keeps the flow of material, without lifting function. Its specialized design minimizes complexity, ensuring reliability in diverse settings—from heavy machinery plants to large-scale factories.

Why did you choose these AGVS?

Automated guided vehicles with natural navigation, such as LY-AK-20 T-1-4 B, can provide power, flexibility and reliability. They can reduce costs and improve security by saving labor, and they can be easily expanded with the growth of business. These AGVS are backed by Yu Long’s supply chain expertise, and represent a strategic investment in operational efficiency.

With the industries embracing automation, it is very important to guide vehicles automatically by natural navigation. For enterprises seeking competitive advantage, it is not only a choice but also a necessity to adopt these advanced AGVS.