In the rapidly developing field of industrial transportation, the demand for efficient, safe and reliable material handling solutions is greater than ever before. A key innovation to promote the development of this field is the Automatic Guided Vehicle (AGV), which has changed the way of transporting heavy goods inside and between factories. For handling large loads, such as the main engines and drive systems of wind turbines, heavy-duty AGV is a game changer, providing top-level performance indoors and outdoors. Moreover, integrating Process Piping with AGV systems in industrial settings boosts operational efficiency, ensuring smooth material and process flow.

What is an automated guided vehicle (AGV)?

Automatic Guided Vehicle (AGV) is a kind of motor vehicle, which transports goods in factories, warehouses or assembly plants along preset routes. Also known as AGV system, autonomous guided vehicles or automatic guided vehicle, it runs without continuous manual supervision and uses advanced navigation and control systems to accurately complete task. From moving small assembly line components to heavy wind turbine parts, the versatility of AGV technology enables it to meet specific requirements.

The Heavy Duty AGV: A Specialized Solution for Heavy – Load Handling

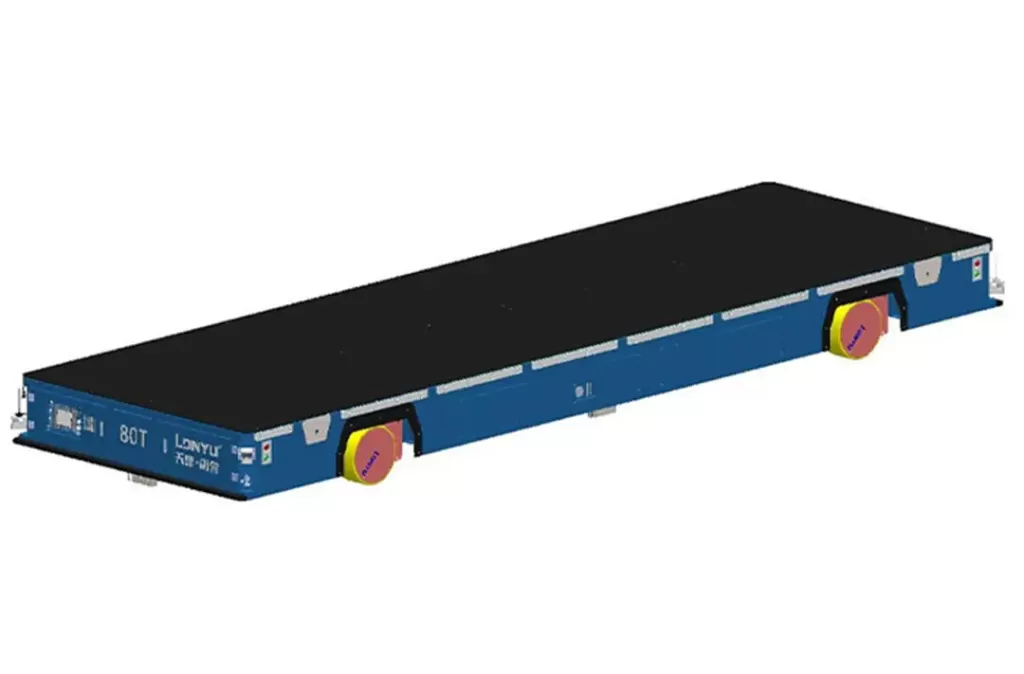

While standard AGVs work for light to medium – duty tasks, the heavy duty AGV is built for tough heavy – load jobs. The rated load is 200 tons, which can easily operate the main engine of the wind turbine, and the weight of 30 tons ensures stability under the maximum load.

Unique Advantages of the Heavy Duty AGV (Model 24111 A)

· Dual – Environment Operation: Unlike many indoor – only AGVs, the Model 24111, a heavy duty AGV, works indoors and outdoors – essential for wind energy projects, where components move from indoor storage to outdoor installation. Its IP 54 protection class enables it to withstand harsh outdoor conditions, such as dust, rain and temperature changes, without performance problems.

· Powerful Drive System: With eight – wheel drive, sixteen – wheel configuration, low – voltage servo motors, and independent servo controllers, this heavy duty AGV has great power and traction. Its driving system (including wheel, servo motors, planetary reducer, chains, shell, slewing bearings and hydraulic cylinder/spring) can ensure smooth movement on uneven surfaces. Hydraulic suspension increases the stability and protects the precise wind turbine parts.

· Accurate navigation and positioning: it has a navigation and positioning accuracy of 10 mm, and allows easy route change through magnetic stripe navigation. Although it is sensitive to metal interference and mechanical damage, it’s reliable in controlled wind energy facilities.

· Efficient energy management: it is powered by a lithium iron phosphate battery, and the battery life is 3 hours (fully loaded or unloaded). Manual charging is required, but the long service life minimizes downtime, which is very important for delaying the expensive wind energy facilities.

Main application scenarios of heavy-duty type 24111 A)

24111 a heavy-duty AGV mainly transports the main engine and transmission system of wind turbine indoors and outdoors. In wind energy facilities, it transfers the engines from production lines to the warehouse, then to outdoor wharf, transported to installation sites, and even put the components on towers for correct assembly.

In addition to wind energy, heavy AGV systems are also used in automobiles (moving body/engine group), aerospace (transporting large aircraft parts) and construction. When combined with Process Piping (which moves production fluids/gases) in manufacturing, automated guided vehicle and heavy duty AGV systems streamline production, delivering materials on time to cut delays.

The Future of Automated Guided Vehicle and Heavy Duty AGV Technology

With the adoption of automation and digitalization in industry, automatic guided vehicle and heavy AGV technology will develop. Future upgrades may include AI/ML for better navigation and decision-making, advanced batteries for faster charging and longer life, and 5 G for real-time AGV communication to improve coordination in large facilities.

In a word, automatic guided vehicle (AGV) and heavy AGV are very important for industrial transportation, especially for heavy items such as wind turbine parts. Model 24111 A heavy-duty AGV, with its powerful specifications, advantages and dual-environment use, shows how this technology can change the movement of materials. When used in conjunction with process piping, it can further improve the efficiency. The future of automated guided vehicle and heavy duty AGV is promising, with more advanced solutions ahead.