Driven by the accelerated transition to renewable energy and the increasing demand for power grid stability, the global energy storage industry is experiencing unprecedented growth. According to the forecast of the International Energy Agency (IEA), the global energy storage capacity is expected to increase from 170 GW in 2024 to more than 800 GW by 2030, an increase of nearly five times (Source: https://www.iea.org/reports/energy-storage). As energy storage systems become larger, more complex and more common, the demand for efficient, safe and automated material handling has never been greater, from utility-scale battery farms to industrial storage facilities. This is where heavy AGV (Automatic Guided Vehicle) technology plays a critical role, which completely changes the transportation, assembly, and maintenance processes of heavy energy storage equipment. A reliable agv manufacturer can design a customized automatic guided vehicle system to solve the unique challenges in the field of energy storage, from heavy-load capacities to high-precision positioning, and seamlessly integrate with existing production and storage workflows.

What is heavy AGV, and how does it adapt to the energy storage industry?

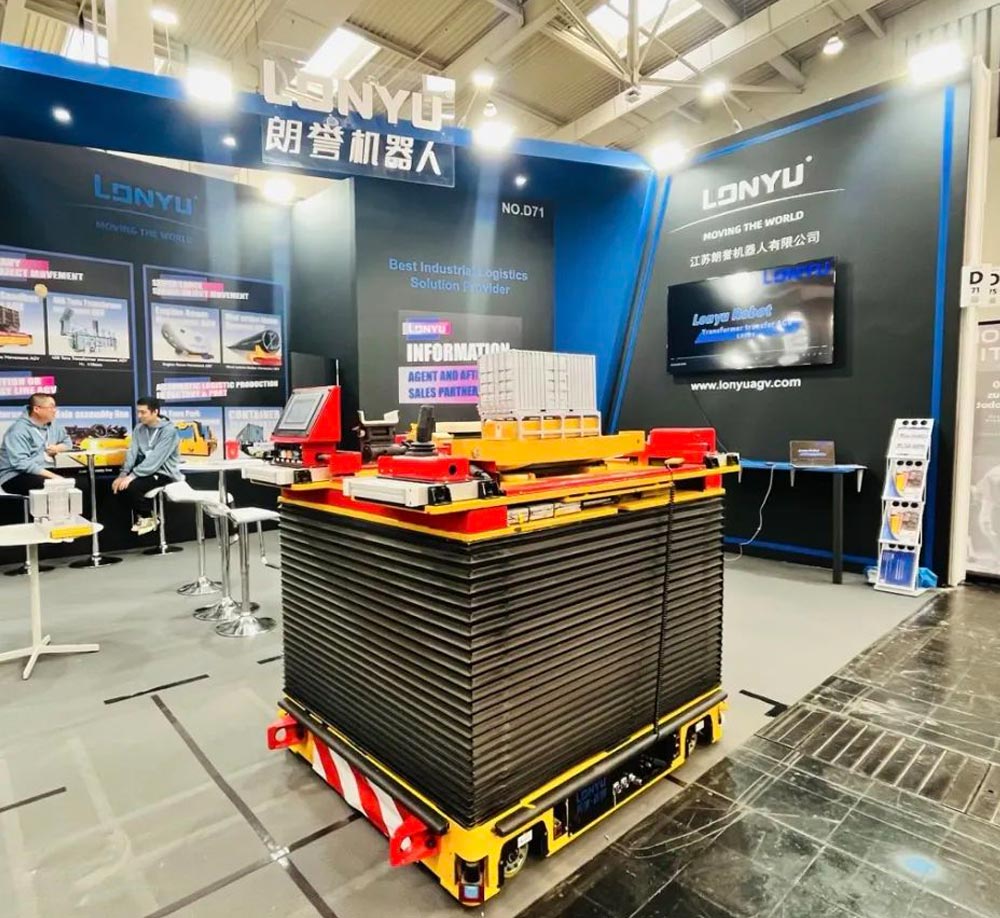

It is very important to define the difference between heavy-duty AGV and standard AGV before studying its application in depth. A heavy AGV is a special automatic guided vehicle, which is designed to handle loads of 5 tons or more. Some models can carry 100 tons while maintaining stability, accuracy and safety. Different from the traditional AGV used in light manufacturing or warehousing, heavy AGV used in energy storage industry aims to meet the unique requirements of this industry: transporting large energy storage containers, heavy battery modules, inverters and transformers and other large components, usually in a limited or complex environment.

A famous AGV manufacturer customized these vehicles through several key adaptation measures to meet the specific needs of the energy storage industry: high-load-bearing frames made from reinforced Q235AF steel to prevent deformation, advanced navigation systems (5 mm to 10 mm) for precise positioning, omni-directional mobility for navigation in narrow spaces—an essential feature of omnidirectional lifting AGV—and powerful safety functions to deal with the dangerous nature of energy storage equipment (for example, High voltage batteries) AGV-supported system also includes centralized dispatching software, real-time monitoring tools, and seamless integration with enterprise systems such as MES (Manufacturing Execution System) and WMS (Warehouse Management System) to ensure end-to-end automation and data traceability.

According to the data of MHI Material Handling Research Institute, heavy-duty automatic guided vehicles are becoming more and more important in industries with high load demand. It is predicted that the CAGR of the global heavy-duty automatic guided vehicle market will increase by 12.3% from 2024 to 2030, mainly driven by the energy storage and renewable energy industries (Source: https://www.mhi.org/reports/agv-market-trends). This growth emphasizes the key role of heavy AGV technology in effectively expanding energy storage industry.

Main advantages of heavy AGV system in energy storage applications

Using heavy AGV technology in the energy storage industry provides many benefits and solves long-term pain points, from inefficient manual processing to safety risks. The following are the most significant advantages of automated guided vehicle system:

1. Unparalleled efficiency and productivity

Heavy energy storage equipment (such as 20-60 tons of energy storage containers or 1-5 ton of battery modules) is slow in manual handling, labor intensive, and easy to be delayed. A heavy AGV runs continuously without fatigue, which reduces downtime and improves throughput. For example, the heavy-duty AGV system deployed in an energy storage container manufacturing facility can transport containers between assembly stations at a constant speed (stepless speed regulation) of 0.1 m/s to 1.5 m/s, which shortens the handling time by 40-50% compared to manual or crane-based handling. The AGV system can also dynamically optimize the route planning, avoid bottlenecks, and ensuring that equipment can be delivered accurately at the required time and place, which is in perfect coordination with the production plan.

2. Enhanced security and reduced risk

Energy storage equipment often involves high-voltage components, flammable electrolytes, and heavy loads, making safety a top priority. Heavy AGV systems are equipped with multi-layer safety protection, including 360 laser obstacle avoidance, three-dimensional visual recognition, mechanical anti-collision mechanisms, sound and light alarms, emergency stop buttons and explosion-proof battery protection. These functions eliminate the risk of human error, such as collision or equipment tilting, which can lead to costly damage, injuries and even fires. A reliable AGV manufacturer can also ensure that heavy-duty AGV meet IP 54 (indoor) or IP 65 (outdoor) protection standards to prevent dust and liquid from invading the harsh energy storage environment.

3. High Accuracy and Flexibility

Energy storage applications require precise positioning, such as installing battery modules into containers or aligning storage containers with power conversion systems (PCS). The heavy-duty AGV systems uses advanced navigation technologies, such as laser SLAM, 3D visual SLAM or laser+two-dimensional code hybrid navigation, to achieve positioning accuracy of 5 mm to 10 mm, and ensure seamless docking without collision or dislocation. Additionally, all-directional heavy duty AGV models (equipped with Mecanum wheels or eight differential wheels) can move forward, backward, sideways, and rotate in place, saving up to 40% of turning space and adapting to narrow, equipment-dense environments like energy storage factories or warehouse facilities. This flexibility makes them ideal for mixed-line production of multiple energy storage equipment types.

4. Seamless integration and data traceability

A high-quality automatic guided vehicle system from a leading agv manufacturer is seamlessly integrated with existing energy storage workflow, including MES, WMS, PCS monitoring systems and digital twin platforms. This integration enables real-time data sharing, allowing managers to track the location, state and movement history of each device. The heavy-duty AGV systems also includes a data traceability module, which can automatically read unique identifier (QR code or RFID tags) on energy storage equipment and record the transportation time, route, operator and equipment status. This traceability is essential to comply with the regulations and quality control standards of energy storage industry.

5. Cost Savings and scalability

Although the initial investment of heavy-duty AGV system may seem large, the long-term cost savings are huge. By replacing manual labor and reducing equipment damage, heavy AGV systems can reduce labor costs by 70% or more, and eliminate quality loss caused by operational errors. Thanks to the optimized route planning and energy-efficient drive system, they can also reduce energy consumption by 30% compared to traditional handling methods. Furthermore, automated guided vehicle system is highly scalable—additional heavy duty AGV units can be added easily as energy storage facilities expand, making them a future-proof investment for growing businesses.

Core Specifications for heavy AGV for energy storage applications

A trustworthy AGV manufacturer will customize the specifications of heavy-duty AGV to meet the unique needs of different energy storage schemes. Below is a table outlining the core specifications and typical ranges for energy storage-focused heavy duty AGVs, based on industry standards and real-world applications.

| Specification Category | Key Indicator | Typical Range for Energy Storage | Application Adaptation Notes |

| Load Capacity | Rated Load | 5T – 80T+ (Mainstream: 20-60T) | 1-5T for battery modules; 20-60T for standard storage containers; 80T+ for large custom equipment |

| Load Capacity | Maximum Lifting Height | 0.1m – 1.2m | ≥0.3m for container docking; ≥0.8m for warehouse stacking |

| Navigation & Positioning | Navigation Method | Laser SLAM, 3D Visual SLAM, Laser+QR Code, Laser+GPS | Indoor: Laser SLAM; High-precision: Laser+QR Code; Indoor-outdoor: Laser+GPS |

| Navigation & Positioning | Positioning Accuracy | ±5mm – ±10mm (Core Scenarios: ≤±10mm) | ±5mm for high-precision module installation; ±10mm for container docking |

| Mobility | Movement Mode | Omnidirectional (Mainstream), Bidirectional | Omnidirectional for narrow indoor spaces; Bidirectional for outdoor use |

| Mobility | Operating Speed | 0.1m/s – 1.5m/s (Stepless Speed Regulation) | ≤1.0m/s for heavy containers; 1.5m/s for battery modules |

| Battery & Charging | Endurance Time | 8h – 24h (Auto-charging/Fast Battery Swap) | 24/7 operation requires auto-charging (≤2h charging time) |

| Safety & Protection | Protection Level | IP54+ (Indoor: IP54; Outdoor: IP65) | Resists dust and liquid intrusion in harsh energy storage environments |

Typical Applications of heavy AGV in energy storage industry

Heavy duty AGV technology is used throughout the entire energy storage value chain, from manufacturing and assembly to warehouse storage and on-site construction. A reliable agv manufacturer will design the AGV systems according to each specific application scenario to ensure the best performance and efficiency. The following is the most common use case.

1. Energy storage container manufacturing

This is the core application scenario of heavy-duty automatic guided vehicles. Energy storage containers (20-60 tons) need to be handled accurately during assembly process, including battery module loading, container shell transportation and finished product transfer. Heavy AGV is equipped with omni-directional movement and laser +QR code mixed navigation, which transports containers between assembly stations to ensure accurate alignment with module installation equipment. For example, a heavy duty AGV system deployed by a leading AGV manufacturer for a global energy storage giant enabled 24/7 continuous operation, increasing overall efficiency by over 50%, eliminating handling damage, and reducing labor requirements from 6-8 workers to 1-2 system monitors.

2. Transportation of battery assembly

Battery modules (1-5 tons) are frequently transported in the production process-from battery assembly and testing to packaging and storage. Heavy AGV designed for this situation is light and flexible, and equipped with laser SLAM navigation, which enables them to effectively pass through dense production lines. They also have a flexible loading platform to prevent the battery from being damaged due to squeezing or collision. The heavy-duty AGV system deployed in a battery module factory improves the transportation efficiency by 60%, and realizes the complete traceability of the movement of each module, ensuring that it meets the quality control standards.

3. Energy Storage plant construction

Outdoor and semi-outdoor energy storage factories need to transport heavy equipment (such as storage containers, PCS devices and transformers) from transport vehicles to installation sites. In this case, the heavy AGV is equipped with laser +GPS dual-mode navigation (for seamless indoor and outdoor switching), high off-road driving systems (for dealing with slopes up to 15° and uneven terrain) and IP 65 protection (for resisting bad weather). They replace traditional cranes, improving flexibility and safety while reducing construction time by 30%.

4. Energy storage equipment warehousing

Finished product storage equipment and raw materials are stored in warehouses, which requires efficient stacking and inventory turnover. Heavy duty AGV used for warehousing is equipped with a high lifting mechanisms (containers with up to 4 floors can be stacked), and it is seamlessly integrated with WMS systems, allowing them to automatically manage inventory. The heavy-duty AGV system deployed in an energy storage warehouse improves the space utilization rate by 40%, the inventory counting efficiency by 80%, and eliminates the mismatch between inventory and materials.

Frequently Asked Questions

In order to help industry professionals better understand heavy AGV technology and its applications, the following is an expert’s answer to common questions from a leading AGV manufacturer.

Question 1: What factors should I consider when selecting a heavy AGV for energy storage facility?

Answer 1: The key factors to be considered are load capacity (matching the weight of your equipment), navigation method (adapted to indoor/outdoor environment), positioning accuracy (meeting your docking requirements), safety function (explosion-proof, obstacle avoidance) and integration ability (with MES/WMS systems).

Question 2: How long does it take to deploy a heavy AGV system in an energy storage facility?

Answer 2: The deployment time varies according to the complexity of the system and the number of AGVs, but it is usually between 6 and 12 weeks. Including 1-2 weeks of demand investigation and scheme design, 2 2-6 weeks of on-site deployment, 2 2-6 weeks of on-site deployment and debugging, 1-2 weeks of trial operation and optimization, and 1 week of acceptance and training.

Question 3: Can heavy AGV run in energy storage facilities all day?

Answer 3: Yes. The heavy-duty AGV is designed for continuous operation with a battery life of 8-24 hours. They support auto-charging (charging time ≤ 2 hours), fast battery swap (≤ 5 minutes), and wireless charging (for hazardous areas), ensuring they can operate 24/7 without manual intervention. The AGV system also includes battery monitoring tools to predict charging demand and avoid downtime.

Question 4: How does the heavy AGV integrate with digital twin platforms in energy storage equipment?

Answer 4: The heavy-duty AGV systems transmits real-time data (including position, speed, task progress and battery status) to the digital twin platform, which can build 3D virtual model of the AGV and the facility. This enables managers to monitor operations in real time, optimize routes, predict equipment failures, and simulate changes to the layout of facilities.

Question 5: Is the heavy-duty automatic guided vehicle cost-effective for small and medium-sized energy storage enterprises?

Answer 5: Yes. Although the initial costs may be higher than that of manual handling, heavy AGV systems provide long-term cost savings by reducing labor, reducing equipment damage and improving efficiency. Many AGV manufacturers offer modular customization options for small and medium-sized enterprises, allowing them to start with a small amount of AGV and expand with its growth, thus reducing the upfront investment costs by as much as 28%.

The Future of heavy AGV technology in energy storage industry

As the continuous development and progress of energy storage industry, heavy AGV technology will become more and more important. Driven by advancements in AI, 5G, digital twin, and green energy technologies, the future of heavy duty AGVs will focus on greater intelligence (AI-driven autonomous decision-making), higher load capacities (100 t+), deeper integration with other automated systems (e.g., humanoid robots), as well as greener operation (hydrogen fuel cells, energy recovery systems) A forward-thinking agv manufacturer will continue to innovate and develop an automatic guided vehicle systems to meet the growing needs of the energy storage industry and support its transition to a more sustainable and efficient future.

In conclusion, heavy duty AGV technology is a game-changer for the energy storage industry, addressing the sector’s unique challenges of heavy load handling, precision, safety, and efficiency. By cooperating with a trusted AGV manufacturer to implement a customized automatic guided vehicle system, energy storage enterprises can improve productivity, reduce costs, enhance safety and realize digital transformation, thus achieving success in the fast-growing market. Whether you are manufacturing energy storage containers, transporting battery modules, building a utility-scale storage factory, or managing a warehouse, the heavy-duty AGV system can help you overcome the most pressing material handling challenges and achieve new efficiency levels.