In the era of Industry 4.0, smart factories integrate industrial artificial intelligence, big data, digital twins and the Internet of Things to realize automatic, visual and traceable production, breaking the bottlenecks of traditional manual-driven manufacturing. As a core flexible logistics equipment, heavy duty agv (rated load ≥ 1T) has emerged as a game-changer, solving the long-standing pain points of heavy material handling—such as low efficiency, high labor costs, and safety risks. Different from ordinary light-load AGVs, heavy duty AGVs are designed to handle materials ranging from tons to tens of tons, which makes them indispensable tool for heavy industries. Combining authoritative data, core technologies, typical scenarios and practical selection guidelines, this paper interprets its application value in smart factories, focusing on providing operational opinions for enterprises seeking logistics automation upgrade.

Core Definitions

- Heavy Duty AGV: A smart mobile device specifically designed for ton-levelo dozens of ton – level material handling, transfer, docking, and stacking. It adopts high rigid frame and multi-drive system to ensure stable operation under heavy load conditions, and is equipped with advanced navigation and safety systems to adapt to complex intelligent factory environment.

- Smart factory: A modern factory model centered on efficiency improvement, cost reduction, and safety guarantee, which integrates cutting-edge technologies to realize the automation and intelligence of the entire production process. In such factories, heavy agv acts as a bridge connecting production lines, warehouses and processing stations, forming a seamless and efficient logistics loop.

- System Integration: The seamless connection between the heavy duty agv system and upper-level management systems such as MES (Manufacturing Execution System), WMS (Warehouse Management System), and RCS (Robot Control System). This integration realizes real-time data interoperability and collaborative operations, ensuring the perfect synchronization of material transfer and production rhythms.

According to authoritative data of the Automation Promotion Association, from 2025 to 2030, the demand for heavy duty agv in global smart factories will grow at a stable compound annual growth rate (CAGR) of 17.9%. By 2030, the market scale of heavy duty AGV is expected to account for more than 44% of the whole AGV industry, which reflects its growing importance in global manufacturing transformation. The report also emphasizes that smart factories with heavy agv and mature automated guided vehicle system have achieved remarkable operational improvements and become a key competitive advantage in this industry.

Core Technologies

The stable and efficient operation of heavy duty agv depends on its core technical parameters and scientific system architecture. These parameters directly determine its adaptability to different smart factory scenarios. The following is a detailed table of key technical parameters, including their typical scope and application impacts, and then the introduction to the three-in-one technical architecture:

| Technical Parameter Category | Typical Range | Application Impact Description |

| Loading Capacity | 1T to 50T or more | It is suitable for different heavy-duty scenes, from automobile parts (1-3 tons) to energy storage containers (20-50 tons) |

| Navigation Methods | Laser SLAM, Magnetic Strip, Multi-Sensor Fusion | Laser SLAM used in flexible production lines; Magnetic stripe for fixing the paths; Multi-sensor fusion in complicated environment |

| Location accuracy | ±5 mm to ±10 mm | 5 mm for aerospace high precision applications; 10 mm, used for conveying and assembling common materials |

| Security and guarantee | 360 ° laser Obstacle Avoidance, 3D Visual Recognition, Mechanical Anti-Collision, Sound-Light Alarm | Multi-layer safety barriers are formed to avoid damage to personnel and equipment, especially in high-risk environments |

In addition to the above key parameters, the heavy duty agv also adopts a three-in-one technical architecture-hardware implementation, software scheduling and security protection-to ensure stable, intelligent and safe operation. The hardware execution unit provides powerful power and bearing capacity and supports heavy load operations; The software dispatching center realizes intelligent task assignment and dynamic path optimization to adapt to real-time production changes; As mentioned in the table, the safety protection system completely eliminates the potential operational risks.

Unique Advantages

- Efficiency: The heavy agv can work continuously for 24 hours without manual rest, thus avoiding the efficiency loss caused by manual fatigue, shift work and operation errors. According to A3 data, the application of heavy duty agv can improve the efficiency of material handling by more than 50%, and greatly reduce the waiting time of production lines caused by material shortage.

- Cost Reduction: By replacing manual handling, heavy agv can save more than 70% of handling labor costs, and at the same time, it can also reducing additional expenses such as manual training, work-related injury compensation and material losses caused by human error. It is estimated that enterprises can recover the investment in heavy agv within 1.5 to 3 years, which has long-term cost-saving effects.

- Safety: Heavy duty agv can replace manual operation in high-risk environment such as high temperature, high dust, high pressure and heavy load, which fundamentally reducing the risk of personal safety accidents. Its perfect safety protection system can detect obstacles in real time, and take emergency measures such as stopping or bypassing to ensure the safety of personnel and equipment.

- Flexibility: Heavy duty agv is equipped with various navigation methods and switchable accessories (such as forks, fixtures and lifting platforms), which can quickly adapt to the mixed production needs of various varieties and small batches in smart factories. There is no need for large-scale site renovation, which is convenient for adjustment according to changes in production lines and orders.

Typical application scenario

Car production

In the automobile manufacturing industry, the handling of heavy parts such as engines, chassis and cabs is a key link affecting production efficiency and product quality. Dongfeng Huashen, a leading heavy-duty truck manufacturer, has adopted nearly 100 heavy duty agvs (with a single load of ≥ 10T) in its Smart factory. These heavy AGVs are responsible for the automatic transfer of large parts and assembly line docking, and the positioning accuracy is 10 mm to ensure precise matching of parts. After application, the labor cost of the enterprise is reduced by 65%, and the stability of the production line is obviously improved, which is suitable for multi-vehicle mixed-flow production.

Energy Storage system

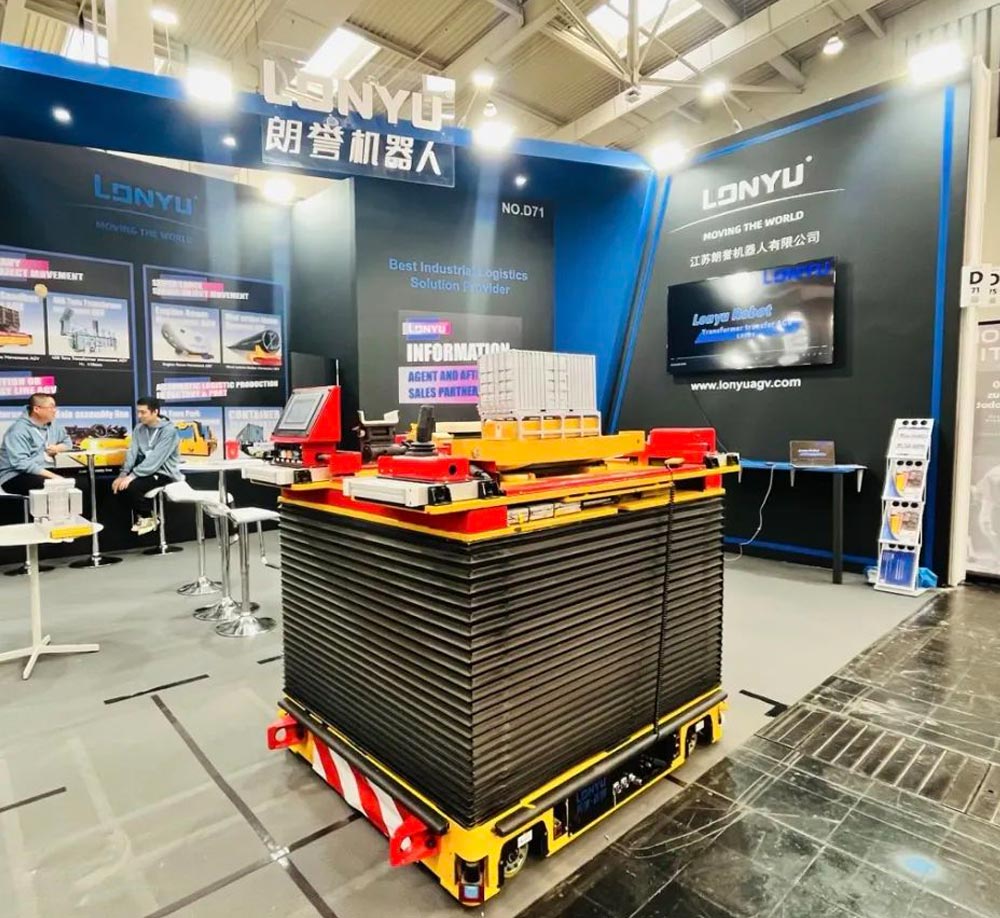

With the rapid development of the new energy industry, the transportation of energy storage containers (weighing several tons to several tens of tons) has become a big challenge for related enterprises. Lonyu, a professional agv robot manufacturer, provides a leading energy storage enterprise with 20-50 ton omni-directional and heavy-duty agv. These heavy duty AGVs are equipped with high-precision navigation systems and intelligent scheduling software, realizing 24-hour continuous operation of energy storage containers from the assembly line to the warehouse. As a result, the logistics efficiency of the enterprise has increased by 50%, and the material loss rate has dropped to near zero, thus ensuring the stability and security of the supply chain of energy storage product.

Metallurgical and Aerospace industries

In metallurgical scene, heavy duty AGV with a load of 25 t is widely used for outdoor handling of finished product hoppers in high temperature and dusty environment, realizing 24-hour continuous operation, and the failure rate is below 0.3%. In the aerospace field, customized heavy-duty AGV with a positioning accuracy of 5 mm is used to transport high-precision aerospace parts, which is suitable for complex road conditions and strict quality requirements and ensuring the safety and reliability of aerospace equipment production.

System integration and selection

System integration is very important to give full play to the application value of heavy duty agv in smart factories. Heavy agv can be integrated with MES and WMS systems through API interfaces to realize real-time synchronization of production tasks and logistics information. It can also collaborate with surrounding equipment such as cranes, high-level shelves, and automatic charging equipment, forming a comprehensive intelligent logistics system. In addition, the virtual operation scene of heavy agv is constructed by using digital twin technology, and the real-time monitoring, path optimization and predictive maintenance of equipment are realized. When choosing heavy duty agv, enterprises should pay attention to four key criteria: scene adaptability (matching load, space and environment), technical performance (navigation accuracy, endurance and safety), integration capability (compatibility with existing systems) and service quality (customization, after-sales maintenance and training). The whole project implementation process, from demand investigation, scheme design to equipment installation, debugging, trial operation and personnel training, usually takes 6-15 weeks.

Frequently asked questions and future trends

Frequently asked questions (FAQ)

Question 1: What are the core difference between heavy AGV and ordinary AGV?

Answer 1: The key difference is the bearing capacity and structural design. Heavy agv is specially designed for handling materials from tons to tens of ton. It has a firmer and more rigid frame and multi-drive system to ensure stable operation under heavy loads. In contrast, the load capacity of ordinary AGV is usually less than 1 t, and the structure is simpler, so it is only suitable for the transfer of light material.

Question 2: what factors should an enterprise consider when choosing a reliable agv robot manufacturer?

Answer 2: When choosing an agv robot manufacturer, enterprises should focus on four core factors: R&D strength (ability to develop advanced heavy-duty agv and automatic guided vehicle system), customization ability (ability to provide solutions that match specific factory scenes), industry experience (successful cases of relevant heavy industries) and after-sales service (including on-site deployment, maintenance and personnel training).

Question 3: Can heavy AGV adapt to harsh working environment such as high temperature and high dust?

Answer 3: That’s right. Heavy duty agv can be customized to adapt to harsh environment such as high temperature, high dust and low temperature. Using industrial-grade sensors and electrical components with strong anti-interference ability, the service life is usually 8-10 years, and the annual maintenance cost accounts for 3-5% of the equipment price.

Question 4: Can heavy AGV be seamlessly integrate with the existing systems of enterprises?

Answer 4: Of course. Heavy agv has strong compatibility, and can be integrated with existing MES, WMS and RCS systems of enterprises through API interfaces or middleware. This integration realizes real-time data exchange and collaborative work, avoiding the waste of existing resources and ensures the synchronization with production rhythms.

Future Trends

Looking forward to the future, with the continuous iteration of industrial technologies, the heavy duty agv in smart factories will develop in four key directions: AI empowerment (realizing autonomous task decision-making and predictive maintenance), deep cooperation (cooperating with humanoid robots and intelligent cranes to build an unmanned logistics system), green energy saving (using new energy batteries to reduce energy consumption), and global standardization (meeting international industry standards and meeting overseas market demand).

Conclusion

As the core equipment of flexible logistics in intelligent factories, heavy agv has solved the long-standing pain points of heavy material handling in traditional manufacturing industry with its advantages of high efficiency, low cost, safety and flexibility. Heavy duty agv has obviously become an important driving force for global manufacturing reform, and is widely used in automobile manufacturing, energy storage, metallurgy, aerospace and other industries. With the continuous upgrading of core technologies and system integration capabilities, heavy duty agv will be more intelligent and integrated in the future. For enterprises planning to transform into smart factories, choosing suitable heavy duty agv equipment and a reliable agv robot manufacturer is the key to realizing logistics automation, improve operation efficiency and enhance the core competitiveness in the industry.