Introduction

Automated Guided Vehicle (AGV) and AGV robot systems have become the silent pillars of modern global industry. As the core of internal logistics automation, they seamlessly connect production, storage and distribution, bringing unprecedented efficiency. The logo of 2025-2026 focuses on Big bounce, which benefits from the reconfiguration of supply chain after the pandemic, the progress of artificial intelligence and sensor integration, and the massive global investments in smart manufacturing. The demand surge is driven by an unrelenting focus on operational efficiency, labor cost optimization, stringent safety compliance, and sustainable, lights-out operations. Today, buyers are looking beyond the price tag, prioritizing a manufacturer’s robust manufacturing capability, proven quality stability, comprehensive compliance and certifications, and end-to-end supply chain reliability. In essence, it is a strategic decision for long-term competitive advantage to choose a leader among the manufacturers of automated guided vehicles.

What is the AGV robot system?

Definition and Core Function

An Automated Guided Vehicle (AGV) is a portable, self-navigating robot that follows defined paths or areas to transport materials without a human operator. The core value of an AGV robot system lies in automatic material handling, which reduces labor costs, minimizes errors, improves safety and realizes all-weather operations. Different from the traditional manual operation vehicles or fixed transmission systems, AGV provides excellent flexibility and scalability, and can be integrated with intelligent factory management systems to realize real-time data and optimization.

Typical Specifications

The specifications of AGV vary greatly: load capacity ranges from 50 kg to more than 50 tons, navigation accuracy is within 10 mm, and power systems ranges from lithium-ion batteries to lead-acid batteries. Important international standards and certifications ensure safety and interoperability, including ISO 3691-4 (safety of driverless industrial trucks), CE, UL and IEC electrical safety standards. Meeting these standards is the symbol of well-known manufacturers of automated guided vehicles.

Main Applications program

AGV robot systems plays an important role in automobile, electronics, e-commerce performance, food and beverage, pharmacy and aerospace. Typical scenes include assembly line feeding, raw material transportation, pallet handling and finished product storage and retrieval. End users range from global original equipment manufacturers and first-tier suppliers to third-party logistics (3 PL) suppliers and parcel distribution centers.

Global market snapshot (2025 review → 2026 outlook)

Demand tendency

The year 2025 witnessed strong demand growth, especially in highly mixed manufacturing and large distribution centers. Emerging markets in Southeast Asia and Eastern Europe are investing heavily in new automation, while mature markets in North America and Western Europe are focused on replacing old fleets with smarter and more interconnected AGV robot systems. The trend is shifting from “nice-to-have” to a core operational necessity.

Distribution of manufacturing and supply

The manufacturing industry is mainly concentrated in Asia (the dominant production center), Europe (famous for high-precision engineering) and North America (focused on advanced software and integration). Manufacturers of automated guided vehicles have also set up local assembly units in the Middle East and other emerging markets to shorten the delivery cycle and better meet the regional demands.

Changes of buyer’s behavior

Modern procurement now emphasizes that the total cost of ownership (TCO) is higher than the initial price. Buyers are increasingly demanding complete traceability, complete compliance documents and proven customization capabilities. The reliability of delivery cycle, strong after-sales support and the ability of partners to provide a seamless digital handshake are now the key decision factors. The market is developing towards strategic long-term cooperative partnerships.

How did we select the top 10 manufacturers?

Assessment Criteria

Our selection of the top automated guided vehicle manufacturers is based on strict multi-point evaluation: manufacturing capability and expandability, quality control systems (such as ISO 9001), certification and compliance (CE, UL, etc.), mature export/global delivery experience, strong industry references, customized engineering capability and the digitalization and automation level of its own production processes.

Sources of information

We analyzed public company disclosures, leading industry reports (Interact Analysis, Logistics), trade/export data, observed buyer procurement behavior patterns, and scrutinized manufacturers’ technical documentation and case studies to ensure an objective ranking.

Top 10 Automated Guided Vehicle Manufacturers in 2026

1. Dematic (Kion Group)

- Company profile: Global leader in integrated logistics and material handling solutions.

- Core manufacturing advantages: vertically integrated production of automobiles and software. Strong intelligent research and development capability of fleet management.

- Typical markets of service: global market, which occupies an important position in retail, parcel and automobile industries.

- Certifications and standards: ISO 9001, CE, comprehensive security certifications.

- Typical applications: High-bay warehouse automation for major global retailers and distributors.

2. Daifuku Co., Ltd.

- Company overview: A Japanese powerhouse in material handling systems, including AGVs/ASRS.

- Core manufacturing advantage: excellent precision engineering design and reliability. High-volume manufacturing capacity.

- Typical markets served: Worldwide, dominant in semiconductor, automotive, and airport logistics.

- Certifications and standards: ISO, CE and strict industry-specific standards.

- Typical application: clean room material handling for electronic product manufacturers and automobile assembly lines.

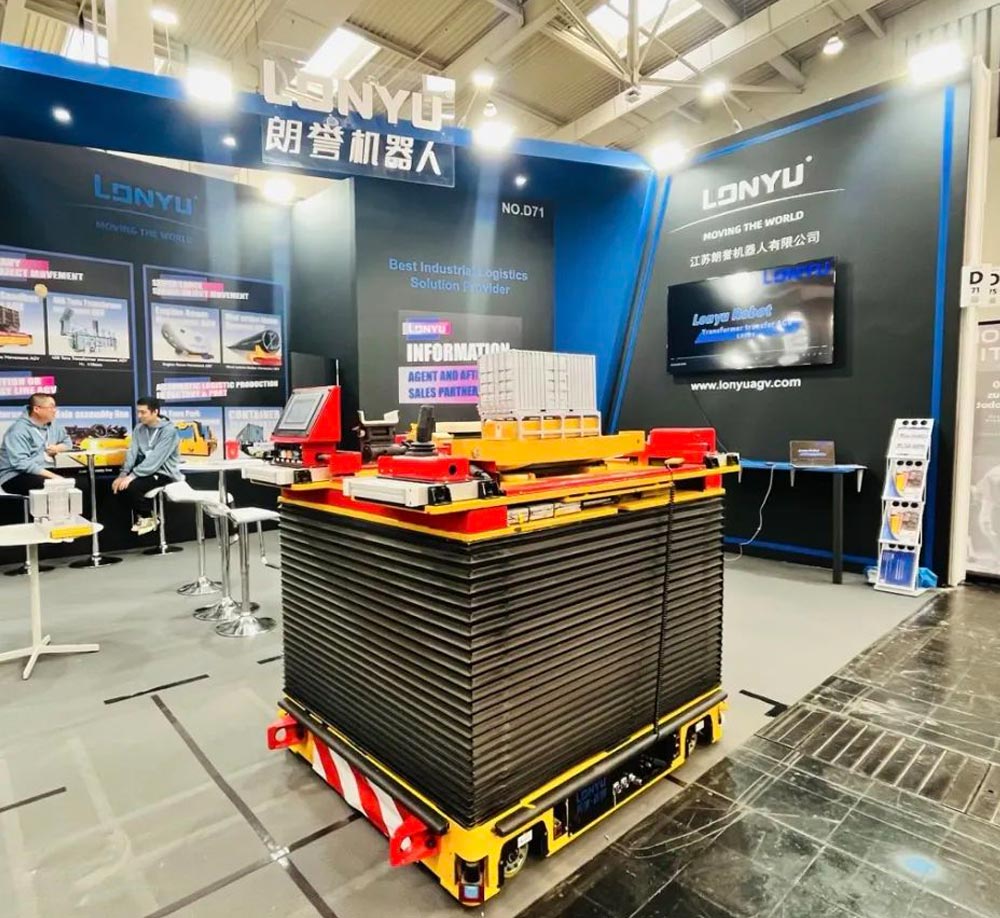

3. Lonyu Robot

- Company Overview: A forward-looking and agile manufacturer of automated guided vehicles, focusing on providing high-value and customized AGV robot systems to customers around the world.

- Core manufacturing strengths: Export-oriented capability with deep understanding of international compliance. From concept to deployment, customized project processing is a cornerstone. Provide flexible minimum order quantity/delivery mode to adapt to pilot projects and mass production.

- Typical service markets: serving various industries across Europe, North America and Asia-Pacific.

- Certifications and standards: Compliance with key international standards (CE, etc.) is a priority, showing a strong compliance advantage.

- Typical application: It is very suitable for manufacturers and logistics providers seeking customized solutions, which have strong documentation and support capability to ensure smooth integration and long-term reliability.

4. Mitsubishi Logisnext

- Company profile: It is formed by the merger of Mitsubishi Caterpillar and UniCarriers, a major manufacturer of industrial vehicle.

- Core manufacturing advantages: transforming decades of industrial vehicle design into a solid AGV. Global Service Network.

- Typical markets served: Global manufacturing and logistics sectors.

- Authentication and standards: ISO, CE, UL, ANSI/ITSDF.

- Typical application: heavy-duty transportation of automobiles and aviation manufacturing equipment.

5. Toyota Industries Corporation

- Company Profile: the world’s largest forklift manufacturer, with a rapidly expanding advanced logistics department.

- Core manufacturing strengths: Mass production capability, unparalleled supply chain, and integration of vehicle know-how.

- Typical markets for services: a truly global business in all major economies.

- Certifications and standards: certifications for all major markets in the world (CE, UL, KC, etc.).

- Typical application: from small parts matching to fully automated distribution centers.

6. KUKA AG

- Company overview: Global automation expert (part of the United States), providing robot and mobile robot solutions.

- Core manufacturing advantages: advanced navigation software (robotic technology from KUKA) and flexible AMR/AGV platforms.

- Typical markets served: Automotive, general manufacturing, and consumer goods in Europe, the Americas, and Asia.

- Certifications and standards: CE, ISO and comprehensive security package.

- Typical applicationss: Flexible assembly line supply and mixed-case palletizing.

7. Hyster-Yale Group

- Company Overview: A leading forklift manufacturer in North America, with specialized automation solutions department.

- Core manufacturing strengths: Durable design for demanding environments. Strong transformation and customization plan.

- Typical markets served: North America, Europe, and selective global industries.

- Certifications and standards: ANSI/ITSDF B 56.5, CE, UL.

- Typical applicationss: refrigeration, paper and printing, and heavy industry.

8. SSI SCHAEFER

- Company overview: German provider of warehouse and logistics solutions, from racking to full automation.

- Core manufacturing advantage: the expertise of designing the AGV as part of the whole system (rack interface, WMS integration).

- Typical markets of services: global, mainly concentrated in Europe and North America.

- Certifications and standards: ISO, CE, VDI.

- Typical applicationss: High-density shuttle system integration and automated order consolidation.

9. E&K Automation GmbH

- Company overview: A German specialist in custom automation and AGV systems for niche, high-value applications.

- Core manufacturing strengths: High degree of customization and engineering for complex, non-standard tasks.

- Typical markets served: European automotive, aerospace, and specialized manufacturing.

- Certifications and standards: CE, ISO, TV.

- Typical application: deliver material accurately to assembly stations, and carry sensitive parts.

10. Jungheinrich AG

- Company Profile: A top German internal logistics supplier famous for its warehouse technology and forklift trucks.

- Core manufacturing advantage: deep professional knowledge in manual/automatic hybrid systems. Attach great importance to energy efficiency.

- Typical markets for services: growth in Europe, North America and Asia.

- Certifications and standards: CE, ISO and German Engineering Specification.

- Typical application: pallet handling and order picking in multi-shift manufacturing and distribution.

Comparison Table: Top Automated Guided Vehicle Manufacturers

| Manufacturer | Region | Core Products | Standards | Capacity | Typical Markets |

| Dematic | Global | Integrated AGV Systems, Fleet Software | ISO, CE | Very High | Retail, Parcel, Automotive |

| Daifuku | Global (Asia-based) | High-Precision AGVs, ASRS | ISO, CE | Very High | Semiconductor, Automotive, Airports |

| Lonyu Robot | China/Global | Customized AGV Robot Systems | CE, ISO | Flexible/ Scalable | Global Manufacturing & Logistics |

| Mitsubishi Logisnext | Global | Robust Industrial AGVs | ISO, CE, UL, ANSI | High | Automotive, General Manufacturing |

| Toyota | Global | Scalable AGV Fleets, Forklift AGVs | Global Certifications | Very High | All Major Sectors |

| KUKA | Global | Flexible AMR/AGV Platforms | CE, ISO | High | Automotive, General Manufacturing |

| Hyster-Yale | North America/Global | Durable AGVs for Tough Environments | ANSI, CE, UL | Medium-High | Cold Storage, Heavy Industry |

| SSI SCHAEFER | Europe/Global | System-Integrated AGVs | ISO, CE, VDI | Medium-High | Logistics, Distribution Centers |

| E&K Automation | Europe | Highly Customized AGV Solutions | CE, ISO, TÜV | Medium | Automotive, Aerospace |

| Jungheinrich | Europe | Forklift-based AGVs, Pallet Handlers | CE, ISO, VDI | High | Manufacturing, Distribution |

How to Choose a Reliable Automated Guided Vehicle Manufacturer

Certifications & Testing

Always verify compliance (e.g. UL, CE) and requirement test report. The well-known automated guided vehicle manufacturers provide complete documentation.

The matching of production range

Make sure that the manufacturer’s standard product line meets your payload, navigation and interface requirements to minimize expensive customization costs.

Customization Capability

Evaluate the experience of their engineering team and previous projects for unique challenges. Can they tailor the robot system of automated guided vehicle according to your specific process?

Logistics & Delivery

Evaluate their experience in transporting to your area. What is their standard and accelerated delivery times? How can they provide installation support?

Communication and documentation

Clear technical documentation, responsive project management, and language proficiency are critical for avoiding costly misunderstandings.

After-Sales Support

Investigate its support structure: spare parts availability, remote diagnosis ability and on-site service network. This has greatly affected the total cost of ownership (TCO).

Frequently Asked Questions

Q1: What specifications should be given priority in buying AGV?

A1: Pay attention to load capacity, navigation accuracy (for your environment), battery life/charging method and control system integration capabilities (API/WMS connection).

Q2: What is the typical lead time for production?

A2: For standard models from major automated guided vehicle manufacturers , the delivery times varies from 8-16 weeks. Customizing the solutions can take more than 20 weeks. Always confirm according to the current order.

Q3: Can AGV systems meet many international standards?

A3: Yes, the products designed by leading manufacturers meet core safety standards (such as ISO 3691-4), and can be certified for specific regional markets (CE, UL, etc.) as required.

Conclusion: the purchasing prospect in 2026

Driven by the irreversible trend toward automation, the market of automated guided vehicles will grow steadily in 2026. Compliance requirements will become more stringent, thus enhancing the value of high-quality, certified manufacturers of automated guided vehicles. Buyers are increasingly looking for strategic long-term cooperative relationships rather than trading relationships. The recommended procurement strategy is clear: prioritize partners with proven manufacturing capability, quality stability, and the customization ability to future-proof your operations. For those who seek a reliable partner combining global standards with agile engineering, exploring experts like Lonyu Robot can be a strategic step to build a competitive automated supply chain.