With the world turning to clean energy, the global wind power generation industry is booming, but the transportation of large parts (wind turbine hubs, generators, blades) is still a bottleneck. Traditional manual or fixed rail methods are inefficient, high-risk, and inflexible—here, cutting-edge automated guided vehicle (agv) technology, especially heavy-duty agv, revolutionizes the sector. The 150 ton heavy AGV (model: LY-1-150 T-816-A) is tailor-made for the transportation demand of wind power generation. This article explores what this heavy duty agv is, its advantages, specifications, and wind power applications, explaining its role in modern wind projects.

What is a 150 ton heavy-duty AGV?

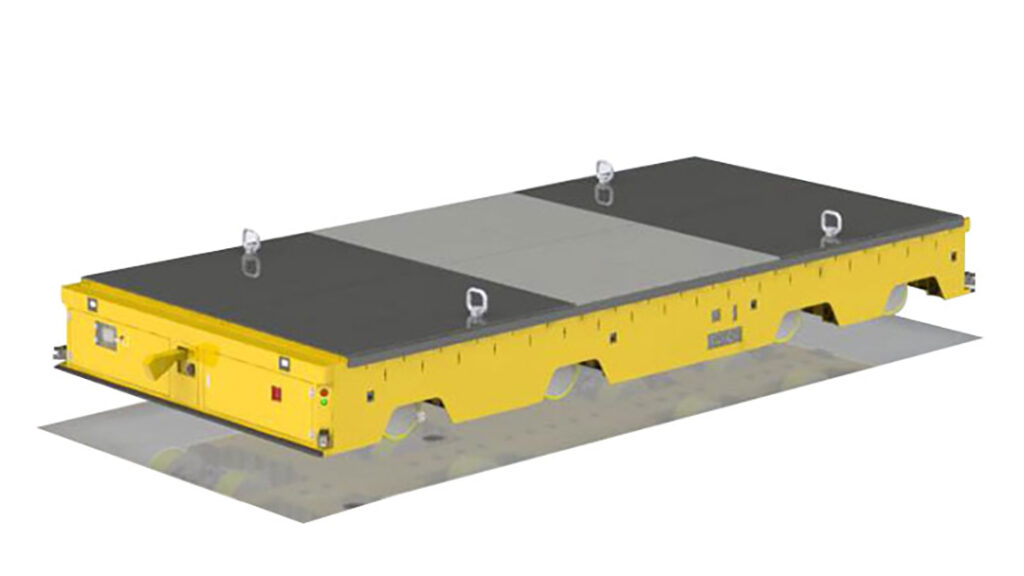

At its core, the 150 ton Heavy duty AGV is a specialized automated guided vehicle handling ultra-heavy loads up to 150,000 kg. Unlike light/medium load AGV, this heavy AGV has a solid structure and can withstand the pressure of wind power generation component. As an automated guided vehicle, it operates with minimal human intervention via advanced navigation, moving safely indoors/outdoors. This autonomy reduces labor costs and errors-which is crucial for expensive and fragile turbine parts. It is not just a means of transportation: it is a comprehensive solution that combines the power, precision and safety for wind power generation together.

Unique advantages of the 150 ton heavy-duty AGV

This heavy agv is superior to other agv and heavy AGV options, which solves the pain point of wind power industry.

1. Excellent load bearing and stability

This heavy agv has a rated load of 150,000 kg and a weight of 35,000 kg, and can handle the heaviest parts (generator stator, turbine hubs) in wind power generation. Its differential drive and 8-wheel drive /16-wheel design ensure uniform weight distribution, improve traction, and prevent damage to the factory workshop or wind farms. Optimized size (7710mm×2888mm×722mm, according to the countersigned drawings) is suitable for large parts, while keeping operability.

2. High-Precision Navigation & Flexibility

The accuracy of wind power components is very important-this automated guided vehicle adopts remote control, and the inching accuracy is 3 mm, which can perfectly align components. It supports forward/backward driving, left/right driving, in-situ rotation and steering (no load/full load), navigation in narrow factory spaces, bypassing wind farm obstacles and avoiding fixed track restrictions.

3. Reliable Suspension & All-Environment Use

The hydraulic passive suspension of heavy duty agv can disperse pressure and absorb impact, protecting fragile blades and level uneven terrain. IP 44/IP 65 protection works indoors (factories) and outdoors (wind farms, resisting dust/rain), making this automated guided vehicle versatile across the wind supply chain.

4. Integrated security

Safety is the key-this AGV has the functions of laser obstacle avoidance (adjusting/stopping for obstacles), contact collision avoidance (physical buffering), sound/light warnings and emergency stop. Its braking is excellent: full load ≤ 500 mm, no load ≤ 300 mm, ensuring safe stop at the maximum weight.

5. Efficient power supply and easy operation

This kind of automatic guided vehicle uses a 96 v/525 AH lithium iron phosphate battery (high density and long life) for long-term shifts work; Manual charging to minimize downtime. Wireless remote control allows the operators to adjust movement safely, while low-voltage servo motors (with independent controllers) can provide a steady speed of 0-30m/min, thus reducing the wear of parts.

Detailed Specifications of 150t heavy AGV (model: LY-1-150T-816-A)

The wind power optimization specifications of these heavy duty AGVs include: model LY-1-150T-816-A; 150,000 kg of rated load (handling the heaviest wind components); 35000kg equipment weight (to ensure stability); 7710 mm * 2888 mm * 722 mm body (per drawings); 200mm lifting stroke (convenient for loading/unloading); Climbing capacity of ≤ 5 (suitable for slopes); Indoor/outdoor running; 8 wheel drive /16 wheel differential drive (uniform weight/traction); Multi-mode motion (no load/full load); Low-voltage servomotor+independent controllers; Hydraulic passive suspension system; Adjustable speed of 0-30m/min; Lithium iron phosphate battery with 96 v/525 AH; 3 mm precision remote control; Wireless operation; Laser/contact obstacle avoidance, acoustic/optical warnings, emergency stop; Manual charge; Braking distance ≤ 500mm (fully loaded) /≤ 300mm (unloaded); IP 44/IP 65 protection. Each specification has optimized this automatic guided vehicle—e.g., 8-wheel drive makes the uneven ground of wind farm flat, and the accuracy of 3 mm makes the components perfectly aligned.

The main applications of wind power industry

The 150 ton heavy duty AGV solves the key wind transportation challenges in three core situations.

1. Factory manufacturing and assembly

Wind power plant produces heavy parts (100+ ton stator). Traditional cranes/forklifts are slow and dangerous-this heavy duty agv can be transported from production to assembly automatically. For example, it is located under a stator, lifted by a stroke of 200mm, and delivered to assembly with a precision of 3, cutting time and errors. Its indoor/outdoor function can be moved from factory to factory without fixed infrastructure.

2. Wind Farm On-Site Transport

After components arrive at the farms, it is difficult to move them on the uneven terrain/gravel. This heavy duty agv travels outdoors with IP 65 protection level, ≤ 5 climb and hydraulic suspension—e.g., Transport 80 tons of wheels from the warehouse to foundations. Laser avoids navigation obstacles, and sound/light warning reminds workers. Unlike trucks (which requires a road module), it moves directly to the website, reducing the needs for preparatory work.

3. Store and retrieve components

Wind facilities store large parts long-term—this heavy duty agv automates storage movement. Its in-situ rotation navigates a narrow spaces and moves multiple widgets or a blade with high capacity. Remote control improves inventory tracking, reducing loss. For example, it saves time/manpower by storing unused blades servers outdoors and quickly retrieving them for installation.

Conclusion

The 150 ton heavy duty AGV (model: LY-1-150 T-816-A) is a professional automatic guided vehicle, which has completely changed the wind transport. Its load capacity, precision, adaptability, and safety outperform traditional methods, meeting wind’s rigorous demands. With the growth of wind power generation, the demand for efficient transportation is also increasing-heavy agv will lead the way. Whether simplifying factory assembly or improving farm efficiency, it uses automated guided vehicle technology to improve productivity and safety.