In the era of Industry 4.0, the stability and intelligent level of logistics automation equipment directly determines the production efficiency of enterprises. As an AGV expert with 600+successful cases, Tianjin Lonyu Robotics, with more than 50% of its r&d team, continues to explore breakthroughs in robot structure, high-performance drive units, collaborative control algorithms, intelligent control software, modularization and scalability, safety and reliability, and innovative solutions for logistics solutions, and continues to provide revolutionary solutions for the global high-end manufacturing field.

The three-dimensional breakthrough system of technical innovation.

1. The gold standard for module design.

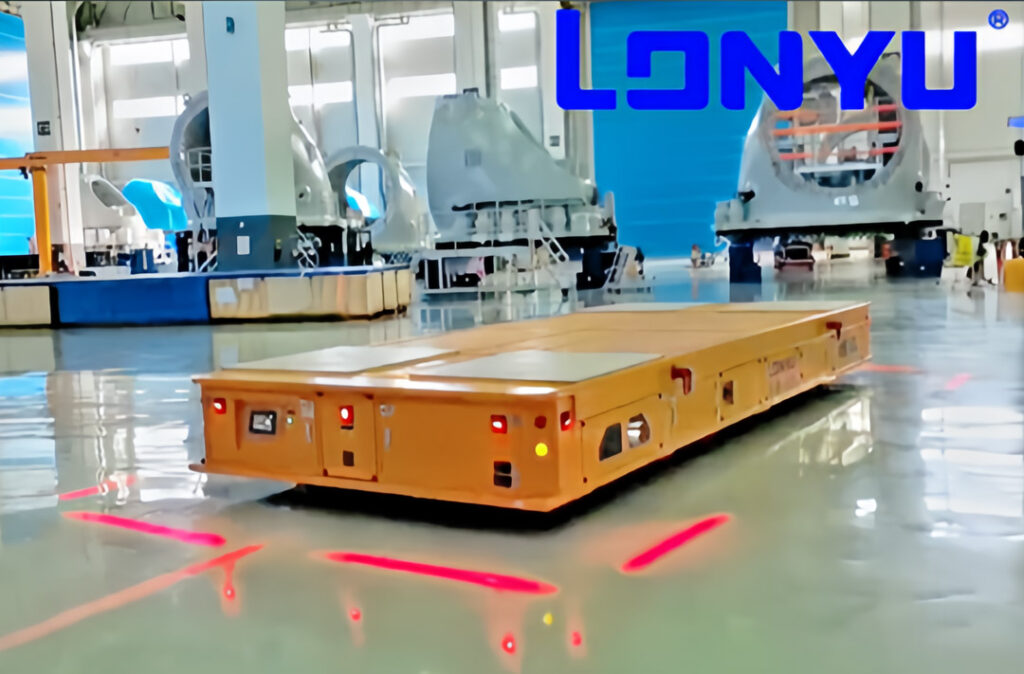

The AGV robot of Lonyu adopts a standardized modular design, and all core components are selected from international first-line brands. The unique hydraulic system ensures safety through the “double insurance mechanism”: in the design stage, leakage analysis is carried out through three-dimensional simulation software; As well as the intelligent spot check system at the use stage, which reduces and eliminates the oil leakage risk.

2. Unique technological advantages

The system has a high technical maturity and unique technical advantages, and the error rate and failure rate are low; The system not only automatically collects equipment data for real-time analysis, but also has the function of fault prediction and analysis, so as to prevent the fault from happening at the first time.

3. The whole life cycle value optimization.

Energy innovation: The SOC (actual power) of lithium iron phosphate battery is not lower than 80% after 2500 cycles.

Cost control: 10 years long service life, 40% higher than competitors. Quick response: Modular design reduces maintenance time by 60%.

Strict quality control creates industry benchmarks.

From IQC incoming inspection to OQC outgoing inspection, Lonyu has established a quality backing: Design stage: software analysis +3 expert reviews.

Production stage: process inspection and process records of each device.

Acceptance criteria: continuous full-load running test for 72 hours.

Cross-Industry Solution Experts

Service network covers many industries around the world, and we have set a benchmark case in these fields:

Aerospace: Material Distribution System in Satellite Manufacturing Workshop.

Port logistics: automatic container transfer project.

The field of new energy: intelligent storage system for wind power blades.

Apart from that, we have also been working in the field of military, high-speed railroad, engineering machinery and equipment, shipbuilding, transformers, and other industries, engineering machinery equipment, ships, transformers, metallurgy, hydropower equipment, heavy trucks, molds and other fields.

“choosing Lonyu is not only a choice of equipment, but also a choice of a partner for ten years. Lonyu is redefining the reliability standard of industrial logistics equipment through continuous technical iterations. Higher quality products can strengthen the strength of the factories. If you have product requirements, please feel free to contact us.

Mailbox in: [email protected]

Telephone number: +86 136 8205 1821