With the scale of wind turbine blades ranging from 2 MW to 15 MW, casting weight exceeds 300 tons. A leading Indian wind turbine foundry is facing a difficult problem: how to deal with these “industrial behemoths”? The traditional methods are completely ineffective at extreme weight and size.

Safety is a daunting task: there are many blind spots in manual operation and there is no overload alarms, which makes the transfer of high temperature castings full of danger.

Efficiency is in a dilemma: manual transfer speed is very slow in a narrow spaces, which has caused a serious logistics bottleneck.

High costs persist: special ground improvement and high management and maintenance costs are eroding profits.

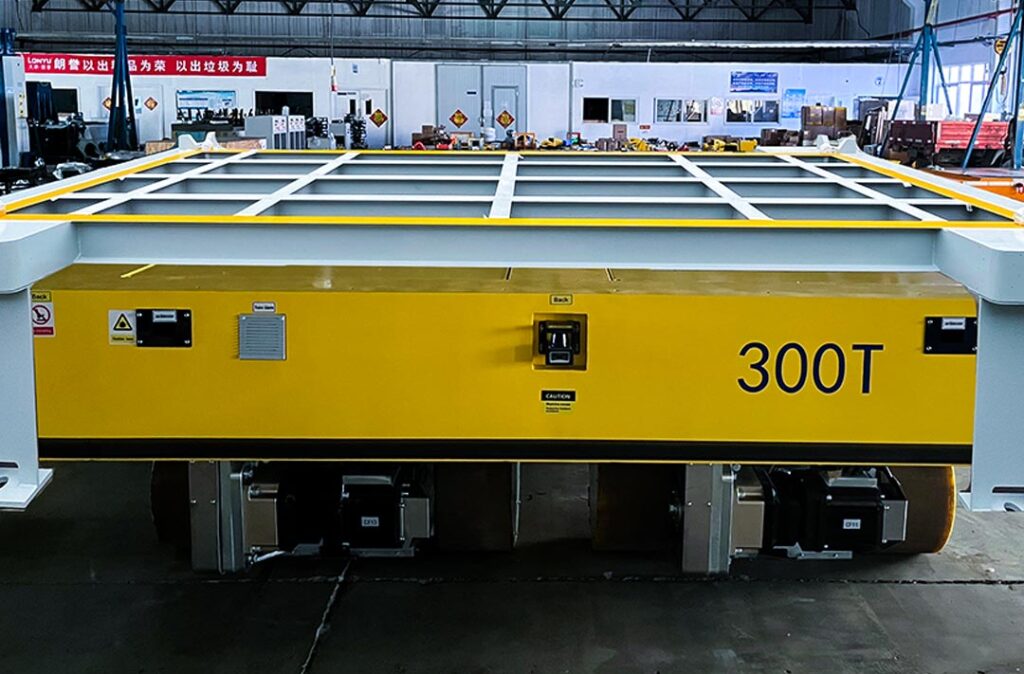

When the global wind turbine giants collectively turned eastward to find the answer, Tianjin, China’s Lonyu Robotics provided a key solution: a 300-ton intelligent heavy AGV solution, which was successfully deployed at an Indian foundry!

Pain Point Eliminator: Lonyu Heavy-Duty AGV’s Core Breakthrough.

Lonyu Robotics solved the core challenges faced by Indian foundries. Its heavy-duty AGV (Automatic Guided Vehicle) provides a set of highly targeted solutions and brings great value to customers.

1. Millimeter-Level Precision Docking: 100% Success Rate Overcoming the Challenge of Oversized Castings.

In order to solve the pain point of accurately handling oversized castings, Lonyu AGV robots uses laser array automatic guidance technology to achieve 100% success rate of docking. This not only safely transported the 300-ton giant castings, but also completely eliminated the errors of artificial vision, creating a safety miracle for transporting overload transformers and giant castings.

2. Intelligent collision avoidance system: automatic deceleration and parking.

To address the risk of collisions in confined spaces, Lonyu AGVs are equipped with a millimeter-level radar wall distance monitoring system. In the process of reverse motion, they will sense the distance of the walls in real time and automatically slow down and stop when approaching. This solution completely eliminates the collision risk caused by manual reversing, making it easy to carry heavy objects in a compact floor space. It can also helps customers make the best use of space and provide high availability and user-friendliness.

3. Stable Operation at high Temperatures: the “heat resistant armor” of industrial AGV.

To address the challenge of equipment failure in high-temperature environments, Lonyu has developed a combined intelligent air cooling and AC temperature control system. The system effectively reduces the temperature of the AGV core components by 15 degrees Celsius, ensures that the heavy AGV can run continuously and stably even under the extreme surface temperature of 60 degrees Celsius in India, and completely eliminating the curse of high-temperature equipment failure.

From Tianjin, China, to an Indian factory: the global value behind a single order.

This first overseas order is not only a milestone for Lonyu Robotics, but also a key step in the globalization of China’s intelligently manufactured heavy-duty AGV technology.

Technical Capability Certification: the successful transfer of 300 tons of castings has verified Lonyu’s leading ability in the field of ultra-heavy automatic guided vehicle robots.

Reshaping Industry Standards: Providing a model for automated and intelligent logistics for global heavy-duty industry.

Building an International Ecosystem: Attracting global partners and accelerating the overseas expansion of China’s heavy-duty industrial AGVs.

The Future Has Arrived: Bringing Heavy-Duty Logistics into the Intelligent Era.

Lonyu’s experience of heavy AGV in India proves that the pain points of handling ultra-heavy transformers and giant castings is not insoluble. Using the technology of Automatic Guided Vehicle (AGV).

1.cost optimization: reduce dependence on labor force, reduce infrastructure and management costs.

2.Intrinsic safety: intelligent obstacle avoidance, temperature control and overload protection to realize “zero collision risk”.

With the global industry reaching the limits in heavy-duty operations, intelligent processing has become the key to success. Lonyu Robotics is using heavy-duty AGVs as a fulcrum to leverage the logistics revolution in industries such as wind power, energy, and heavy industry.