Imagine safely transporting wind turbine blades over 100 meters long in a crowded factory.Traditional methods is troublesome and dangerous. Enter the Dual-Vehicle Linkage AGV Robot–a cutting-edge, intelligent transport solution specifically engineered to tackle the unique logistics challenges of exceptionally long and heavy materials. This innovative technology is transforming the internal material handling in demanding industrial departments.

What exactly is a Dual-Vehicle Linkage AGV Robot?

The core of the dual-vehicle linked AGV system consists of two AGVs that operate in coordination. Unlike a single AGV, these two AGVs are linked via wireless modules to form a tightly integrated transportation platform capable of handling long loads that exceed the capacity of a single AGV.

1. Position and Attitude Monitoring: The key component is the floating plate mechanism connecting the front and rear AGVs. This mechanism integrates tension sensors and angle deflection sensors to continuously monitor relative position deviations and angular shifts between the two vehicles. Additionally, the system uses laser ranging technology to directly monitor the relative positions of the two vehicles during coordinated operation, providing precise distance information.

2. Intelligent Interlocking Control: Coordination commands between vehicles are transmitted via wireless modules. Advanced control algorithms process data in real time from the floating plate sensors, laser ranging system, and each AGV’s own navigation and safety systems. Based on this data, the algorithms dynamically adjust the speed and steering of each AGV to ensure the two vehicles remain precisely aligned and move in synchronized coordination along the predefined path.

Unique advantages: Why choose dual-vehicle linkage?

1. Outdoor Environment: Adaptable to complex outdoor terrain, lithium iron phosphate battery operates normally at -5°C temperature, humidity, and light rain or snow, with 7-hour ultra-long battery life and over 5 years of service life.

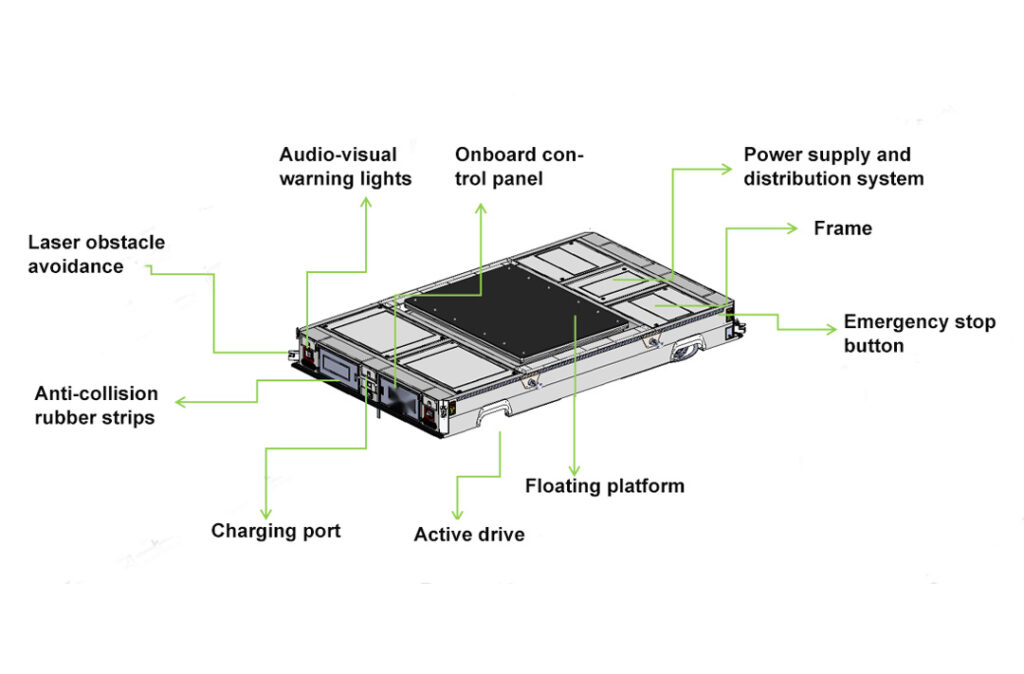

2. Multi-layered Safety Protection: Non-contact laser sensors on the vehicle body + ultrasonic radar + contact-based collision prevention + three-color lights + speakers + emergency stop + wireless emergency stop + remote control emergency stop.

3. Multi-drive collaboration for stable and efficient performance: Utilizes a dual-axis symmetrical drive layout with all-wheel drive structure, featuring a rational design. Four-wheel drive with eight wheels for multi-drive collaborative control, enabling two-dimensional planar omnidirectional movement with ultra-high power. Speed adjustment up to 30 m/min with multi-speed stepless regulation. Speed self-adjustment function.

4. Intelligent hydraulic system + weight detection: Equipped with a hydraulic suspension damping and leveling system to ensure the work platform remains stable and vibration-free. Simultaneously, a multi-point center of gravity detection system determines whether the load exceeds the weight limit.

5. Modular production + high stability + fault prediction + emergency handling: Modular design and production of drive modules, control cabinets, hydraulic systems, etc. The vehicle body undergoes finite element analysis, electrical verification calculations, and collaborative control software, ensuring mature, stable, and reliable performance.

6. Front and rear communication between vehicles is achieved via encrypted Wi-Fi frequency bands using pull-cable sensors and angle deflection sensors to detect vehicle displacement. During dual-vehicle operation, no communication disconnections occur.

Manufacturing: Excellent design

These AGVs are manufactured by using advanced modular manufacturing technology. The key systems are subjected to strict finite element analysis (FEA) to ensure structural strength under maximum load. Electrical systems has been carefully designed and inspected. The core software, especially the complex dual-vehicle coordination logic, is mature and field-proven, resulting in a highly stable and reliable product. Strict quality control flow runs through the whole production process.

The main application Scenarios

Dual-Vehicle Linkage AGV Robots are indispensable in industries requiring the safe, efficient, and precise internal transport of super-long, heavy, or cumbersome materials.

· Wind energy: transporting large wind turbine blades , tower sections and engine rooms in manufacturing plants and yards.

· Aerospace: moving wings, fuselage parts and large structural components of aircraft.

· Railway transportation: handling car bodies, bogies and long track sections of rail cars.

· Shipbuilding: Transporting ship hull sections, large pipes, and prefabricated modules.

· Telecommunications: Moving long antenna masts and large satellite dish components.

· Bridge & Heavy Construction: Transporting pre-stressed concrete beams, large steel girders, and construction modules.

Conclusion: the Future heavy and long load treatment.

The Dual-Vehicle Linkage AGV Robot represents a significant leap forward in industrial automation for heavy logistics. By combining powerful multi-drive systems, intelligent hydraulic stability, powerful encrypted communication and multi-layer security in a modular and reliable platform, it has solved the key challenge of moving long and heavy loads with unprecedented efficiency, safety and accuracy. For industries such as wind energy, aerospace and shipbuilding, this technology is not only an improvement; It’s becoming an important pillar of modernization and automation of internal logistics, raising productivity and safety to new levels.