In the busy environment of modern factories, warehouses and distribution centers, a silent revolution is taking place. You may have seen them: unmanned trolleys transport huge goods smoothly and shuttle between various facilities accurately and purposefully. These are automated guided vehicles, or AGVs, and they are fundamental to today’s automated supply chains. But what exactly is an AGV robot and how does it perform its tasks so reliably? This comprehensive guide delves into the inner workings of AGV technology, explores its significant advantages, and highlights the critical role of the heavy duty AGV in industrial automation.

Defining the AGV: Not just a simple robot

An Automated Guided Vehicle (AGV) is a portable robot that follows markers, wires, or signals for navigation along a predefined path. In more advanced terms, it is a battery-powered unmanned vehicle, equipped with automatic navigation system, such as laser, magnetic or optical aiming system, so that it can drive autonomously throughout a facility. AGV operates under the command of a central control system, and carries out the tasks of material transportation, loading and unloading with high precision, thus improving the efficiency in manufacturing, logistics and other industries.

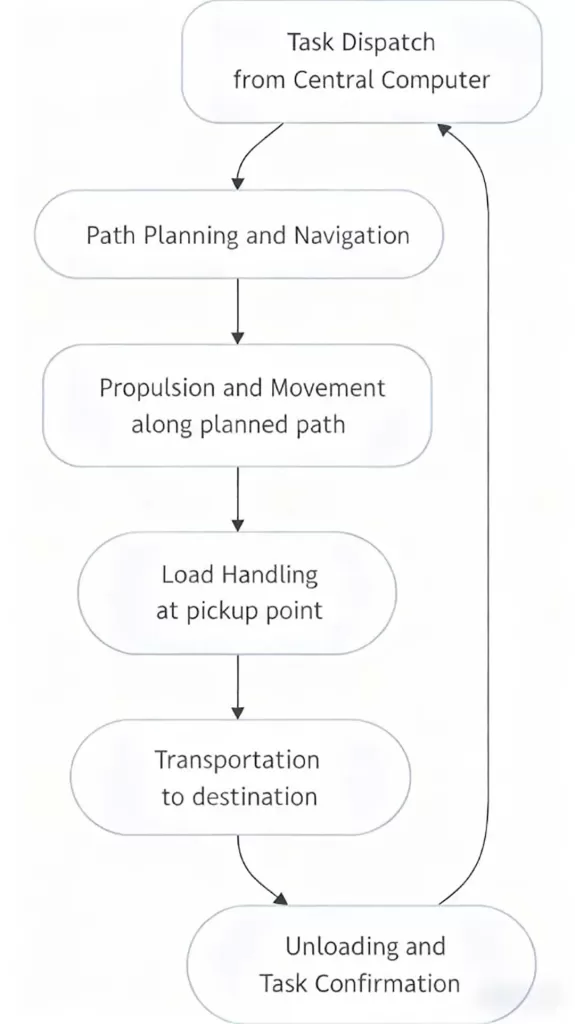

The Step-by-Step Operational Workflow of an AGV

The seamless operation of an AGV can be broken down into a series of interrelated steps, forming a continuous efficiency cycle. The technological process is shown in the following table.

1. Task assignment: When the central fleet management computer receives the transportation request, the cycle begins. This could be triggered automatically by a production management system (such as MES or ERP) or manually by an operator. The system recognizes the available AGV and assigns it the task.

2. Path planning and navigation: This is the intelligent core of the AGV robot. Once the allocation is received, the vehicle determines the best route to the destination. Navigation technologies are different, providing different degrees of flexibility.

- Laser Guidance: The AGV uses rotating lasers to scan its surroundings, calculating its position by triangulation distances to reflective targets installed on walls or columns. This is a highly flexible, marker-free method.

- Magnetic/magnetic tape navigation: the vehicle travels along a magnetic stripe or colored tape attached to the floor. This is a reliable and cost-effective solution for an environment with fixed paths.

- Inertial Guidance: The AGV navigate using dead reckoning with gyroscopes and wheel encoder, periodically correcting its position by scanning built-in markers on the floor.

- Natural feature navigation: the most advanced method, AGV uses on-board cameras and sensors to create a map of its environment, and navigates by identifying natural features (such as shelves and machinery) without any physical guidance.

3. Propulsion and Movement: The AGV moves along the planned path using its drive system. The design of the system is very important, especially for a heavy duty AGV which must transport loads weighing several tons stably and accurately.

4. Load handling: Arriving at the loading point (e.g., Conveyor, shelf or workstation), the AGV performs its specific handling operation. The design varies significantly based on need, including forklift models, underride units, tow tractors, and conveyor-deck types.

5. Transportation: The AGV then transports the load to its destination, adhering to traffic rules, speed limits, and safety protocols managed by the central system to prevent collisions.

6. Unloading and Confirmation: After unloading the material at the target location, the AGV sends a “task complete” signal back to the control computer, making itself available for a new assignment and closing the loop.

The Compelling Advantages of Adopting AGV Systems

The transformation from traditional material handling methods to AGV automation is driven by undeniable advantages that affect safety, efficiency and the bottom line.

- Enhanced safety: AGV robots greatly reduce workplace accidents related to manual forklift operations by automatically moving heavy objects. They are very suitable for repetitive tasks or handling hazardous materials. The Bureau of Labor Statistics reports that a large number of workplace injuries are related to material handling, and AGV can directly reduce this risk.

- Improve productivity and 24/7 Operation: AGV systems does not need to rest, shift or holidays. They can run continuously, thus greatly improving the throughput and uptime.

- Excellent accuracy and traceability: Automation eliminates human error in material handling. Each task is recorded digitally, providing complete traceability for inventory management, process analysis and quality control.

- Extraordinary flexibility: Unlike fixed transmission systems, the path of an AGV can usually be changed by modifying software or repositioning navigation targets. This enables the factory to quickly adapt to the ever-changing production demand or layout adjustments.

- Optimize space utilization: AGV can run in narrower aisles than traditional forklifts, and require less operating space, thus achieving higher density storage and more effective use of valuable floor space.

The Engine of Heavy-Duty Automation: A Look at the Heavy Duty AGV

For aerospace, automobile and heavy machinery manufacturing industries, the ability to carry huge loads is very important. A heavy AGV is designed to handle 2 tons to 20 tons of payloads. The reliability of this kind of vehicle depends on the design of driving device.

The global AGV market is projected to grow significantly, with some estimates valuing it at over USD 4.5 billion by 2030, driven largely by the demand for automation in logistics and manufacturing (Source: MarketsandMarkets Research).

A key difference of high-quality heavy AGV lies in the separation of key functions within the driving unit. As highlighted in the technical comparison provided, an advanced design separates the lifting, rotating, and force-bearing functions into dedicated components. This is in contrast to the simple designs, in which a single complex hydraulic cylinder tries to perform all functions, resulting in higher stress and potential failure points.

For example, in an excellent design.

- Lifting is operated only by a hydraulic cylinders.

- Rotation is managed by a dedicated slew ring bearing, which is more energy-efficient.

- Radial forces produced by the movement is absorbed by an independent optical axis.

This modular method can protect hydraulic seals, extends the service life of parts and simplify maintenance. If there is a problem, only the specific component need to be replaced, thus reducing downtime and cost, which is a big advantage compared with the integral designs.

Frequently Asked Questions (FAQ)

Q 1: What is the main difference between an AGV and an AMR (Autonomous Mobile Robot)?

A: the key difference lies in navigation. An AGV typically follows a fixed, predefined path (wires, tape, or a strict laser-guided route). If there is an obstacle in its way, it will stop and wait for the obstacle to be removed. AMR uses more advanced on-board intelligence and sensors to understand its environment, enabling it to dynamically navigate and find a new route to bypass obstacles without human intervention.

Q 2: How does AGVs drive?

A: Almost all AGV systems are driven by vehicle-mounted rechargeable batteries, usually lead-acid batteries or lithium-ion batteries. They can be programmed to operate during natural interruption (for example. G. Shift changes), enabling near-24/7 operation.

Q 3: Are AGVs safe to work alongside people?

A: Yes, safety is a primary consideration in design. Modern AGV robots are equipped with multiple layers of safety, including physical bumpers, non-contact safety lasers and scanners (LiDAR), and audible/visual warning signals. When obstacles are detected in their path, they will slow down or stop completely.

Q 4: Which industries generally use heavy AGV?

A: the heavy AGV models is indispensable in industries dealing with large and high-value products, including.

Automobile: a moving vehicle chassis, engines and large components.

Aerospace: transport wings, fuselage parts and engines of aircraft.

Heavy machinery: carrying large industrial equipment and parts.

Metals: transport steel coils, steel plates and other raw materials.

Summary

Automated guided vehicle is the cornerstone of modern industrial automation. From understanding its basic operation process to appreciating the complex engineering behind a reliable heavy AGV, it is obvious that this technology is the key driver of productivity, safety and flexibility. With the continuous development of artificial intelligence and the Internet of Things (IoT) technology, the functions of the AGV robot will only continue to expand, further consolidating its role as an indispensable asset in future smart factories and warehouses.