Key Takeaways for Busy Procurement Managers:

Choose for cost-effectiveness: Air Cushion Vehicle

Choose for high performance: Heavy Duty AGV

Expert Advice: For transportation scenarios of extra-large transformers (over 1000 tons), long-term continuous operation, and precise docking installation, we recommend heavy duty AGV.

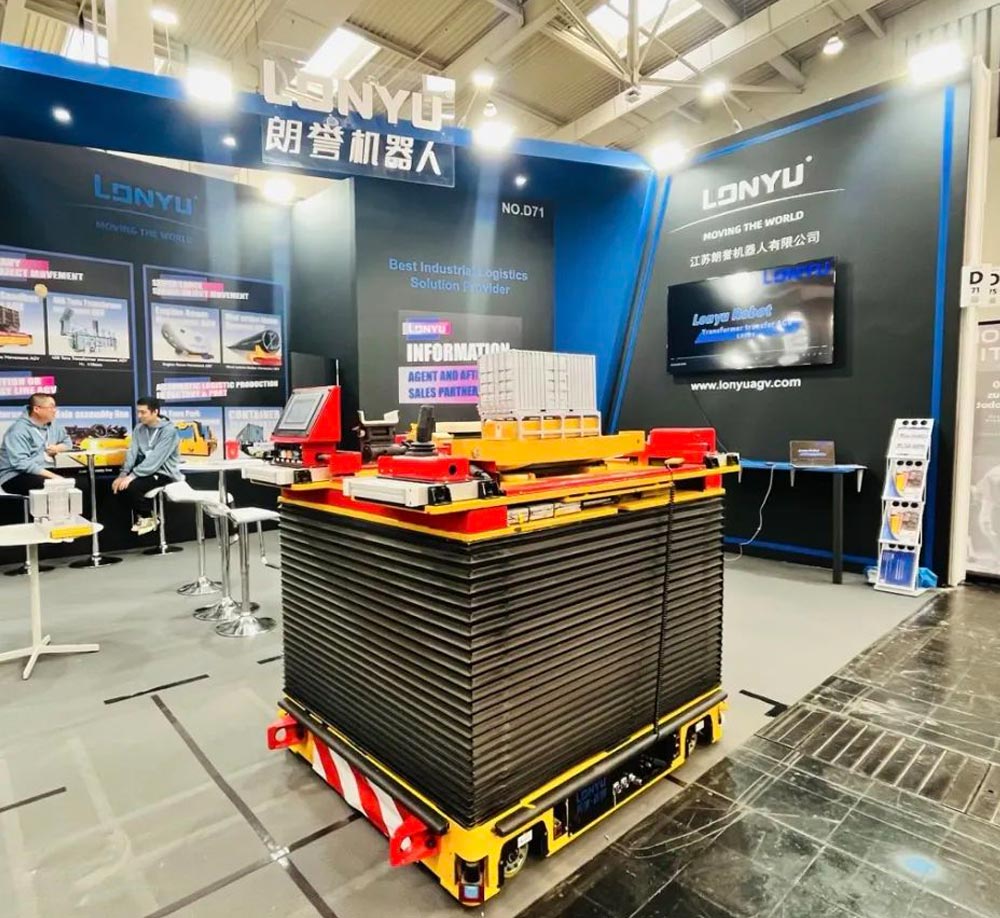

What is Heavy Duty AGV?

Heavy Duty AGV is an automatic guided vehicle, which is specially designed for carrying and transporting overweight loads, usually from 50 tons to over 2000 tons. As an advanced agv robot, it realizes automatic navigation, positioning, and movement through multiple navigation technologies such as laser, magnetic stripe, and vision, without the need for manual driving. It is mainly used to solve the B 2B pain points in the transportation of large-scale precision equipment such as transformers, including high requirements for stability and safety, high labor costs for manual operation, and low efficiency of traditional transportation methods.

Industry standard/generic name: In the field of transformer transportation, it is also commonly called “heavy automatic guided vehicle for transformers”. For related industry standards, please refer to GB/t 26944.1-2011 Automatic Guided Vehicle Part 1: General Technical Conditions and GB/t 26944.2-2011 Automatic Guided Vehicle Part 2: Safety Requirements.

Synonyms: Heavy-duty automated guided trolley, extra-heavy load AGV, transformer transportation AGV.

Core comparison data sheet

| Contrasting parameters | Heavy-duty Automated Guided Vehicle | Air Cushion Vehicle |

| Loading Capacity | Advantage: the upper limit is high, covering 50-1500 tons, and the customized payment can exceed 2000 tons; Uniform stress. Disadvantage: the fixed type has adjustable load capacity and poor flexibility. | Advantage: stable medium load capacity (20-500 tons, up to 800 tons in upgraded models); Adjustable support surfaces. Disadvantage: the upper limit is low, which can’t meet the demand of more than 1000 tons. |

| Mobility and adaptability in site | Advantage: high degree of automation and accurate positioning (5 mm); Flexible movement in confined spaces. Disadvantage: high ground requirements (flatness error ≤ 3mm/m); Temporary route adjustment is slow. | Advantage: the requirement for the ground is low (flatness error ≤ 10 mm/m); Flexible turning. Disadvantage: low degree of automation and poor positioning accuracy (50 mm+); It is unstable when the wind is strong outside. |

| Stability and security | Advantage: Stable operation, low vibration (vibration acceleration ≤ 0.1 g); Perfect security system. Disadvantage: the structure is complex and it is difficult to maintain when it fails. | Advantage: low vibration; The structure is simple and the maintenance is convenient. Disadvantage: Stability depends on air compression system; There is a lack of automatic security monitoring. |

| Cost (initial and operating) | Advantage: low long-term running cost and low failure rate (annual failure rate ≤ 5%); Continuous operation for 24 hours. Disadvantage: high initial investment (several million to tens of millions of yuan). | Advantage: the initial investment is low (hundreds of thousand to millions of yuan); Easy debugging. Disadvantage: high long-term running cost; Continuous operation is not possible. |

| Length of service | 10-15 years (under normal operation and maintenance. | 8-12 years (under normal operation and maintenance. |

| Compliance | Comply with the requirements of GB/t 26944.1-2011 and GB/t 26944.2-2011; Explosion-proof grade of transformer scene ≥ Ex d IIB T 4. | It meets the requirements of JB/t 10605-2006 “Air Cushion Conveyor”; There is no special explosion-proof design for transformer scene. |

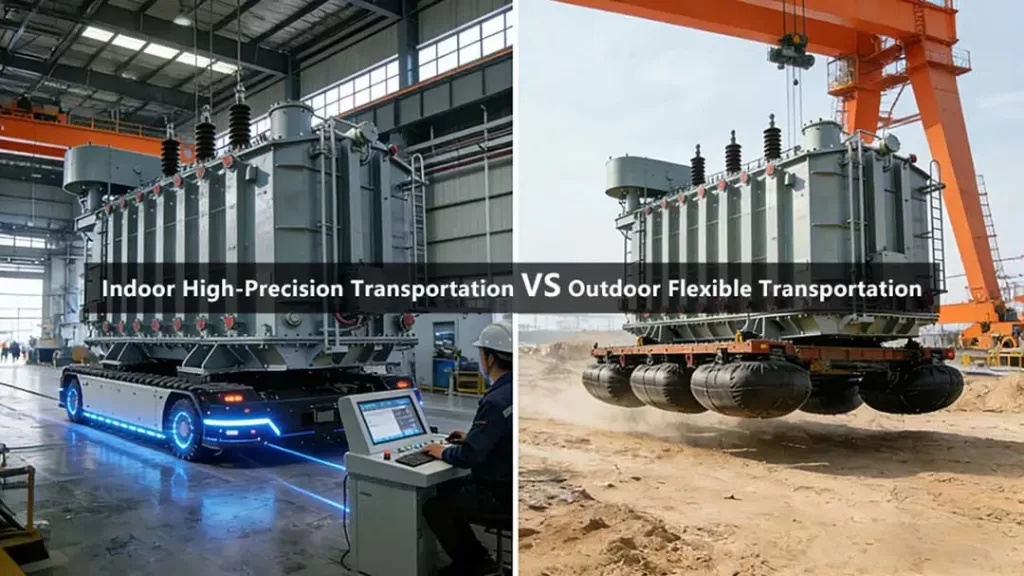

| Application scenes | Super-large transformers, long-term continuous transportation, accurate docking installation and complicated route transportation. | Medium weight transformers, short-distance temporary transportation, outdoor non-precision docking, general ground conditions. |

In-depth Analysis: Why Choose Heavy Duty AGV?

Pain point solution and core advantages after use: heavy duty AGV effectively solves the core B2B pain points in transformer transportation, and its value has been verified by industry data. The in-depth analysis and investment prospect research report of China autonomous vehicle industry (2025-2032) from Yan Guan Report Network shows that the application rate of heavy duty agv in heavy-duty transportation of transformers has surged by 67% in five years, making it the first choice for large manufacturers-mainly because it solves the pain point of high labor costs through full automation. By eliminating the need for professional drivers and auxiliary personnel, enterprises can cut annual transportation-related labor costs by approximately 52%, as noted in the same report. Aiming at the pain point of low transportation accuracy, its 5 mm high-precision positioning technology ensures accurate docking with transformer installation benchmarks, and reduces the rework rate caused by positioning errors from 12% to only 1.5%. Its 24-hour continuous operation ability further ensures the smooth progress of transformer production and installation.

Other key advantages of heavy agv include: 1. Efficiency enhancement: Shortens the average transportation cycle by 38%, accelerating transformer delivery and installation timelines. 2. Safety improvement: reduce the accident rate to below 0.5%, and protect high-value transformers and field personnel. 3. Intelligent management: the supporting control system can monitor and record the transportation process in real time, laying a foundation for the operations of intelligent factory.

How to Choose a Heavy Duty AGV

Step 1: Clarify Requirements

First, determine the key parameters of the transformer to be transported, including weight, volume, and type (oil-immersed or dry-type). Make clear the transportation scenario (workshop transportation, factory short-distance transportation or installation site positioning) and whether it needs continuous operation. For example, to transport 1,000 tons of oil-immersed transformers, which requires 24-hour continuous operation in the workshop, it is necessary to choose heavy duty agv with high load and high stability.

Step 2: Confirm Parameters

Based on the clarified requirements, confirm the key parameters of the heavy duty agv, including rated load capacity (it is recommended to select a model with a load capacity 10-20% higher than the transformer weight), bearing surface size (matching the transformer base), positioning accuracy (static positioning accuracy ≥ ± 5 mm for installation site scenarios), driving speed, and battery life (meeting the daily operation time requirements).

Step 3: Match Standards

Ensure that the selected heavy duty agv complies with relevant national standards (GB/t 26944.1-2011, GB/t 26944.2-2011) and industry norms. For the transportation scenario of oil-immersed transformer, confirm that the equipment has explosion-proof design, and the explosion-proof level is not lower than Ex d IIB T4. At the same time, check whether the equipment’s environmental adaptability meets the on-site conditions (such as working temperature, ground requirements).

Step 4: Verify Suppliers

Select suppliers who are experienced in R&D and production of heavy agv for transformer transportation. Check the qualification certificates, successful cases and after-sales service system of suppliers. It is suggested that the supplier’s workshop be inspected on site to test the equipment performance. Confirm the supplier’s after-sales service content, including installation and debugging, operator training and maintenance support (such as whether there is a 24-hour emergency maintenance hotline).

Frequently asked Questions and answers

Q 1: What is the minimum order quantity of heavy AGV?

A 1: The MOQ is 1 set. Because most heavy duty agvs are customized according to customer ‘needs, we can provide customized services for a single AGV to meet the specific transportation needs of different customers.

Q 2: What is the Delivery Time After Order Placement?

A 2: The delivery time is 60-90 working days after the customized plan is confirmed and the advance payment is received. The exact time depends on the complexity of the equipment and the production schedule. We will issue a detailed production plan and update the progress to our customer on a regular basis.

Q 3: What Certifications Does the Heavy Duty AGV Have?

A 3: The product has passed ISO 9001 quality management system certification, GB/t 26944.1-2011 certification, GB/t 26944.2-2011 certification, and transformer transportation scene explosion-proof certification (Ex d IIB T 4). At the same time, relevant test reports can be provided according to customer requirements.

Q 4: Can the heavy AGV adapt to the different ground conditions of the Factory?

A 4: The heavy duty agv requires the ground concrete strength to be ≥ c 30, the flatness ≤ 3 mm/m, and no obvious cracks or depressions. If the on-site ground does not meet the requirements, we will provide professional suggestions for ground reconstruction. For ground with small undulations, the equipment’s hydraulic suspension system can realize height fine-tuning (adjustment range ± 50 mm) to ensure stable operation.

Q 5: What is the After-sales Maintenance Service for Heavy Duty AGV?

A 5: We provide a 1-year free warranty service (not including wearing parts). During the warranty period, we will send professional technicians to repair any quality problems for free. After the warranty period, we provide lifelong maintenance services, including replacement of wearing parts, software upgrade and equipment overhauls. At the same time, we set up a 24-hour after-sales service hotline to respond to customer ‘maintenance needs in time.

Summary

In the transport of transformers, heavy agv and air cushion vehicles have their own advantages and disadvantages. Air cushion vehicles is suitable for short-distance temporary transportation scenes with medium weight and general ground conditions, and have the advantage of less initial investment. Heavy Duty AGV, as a high-performance automated guided vehicle, has obvious advantages in load capacity, automation, precision, and safety. It is more suitable for the scene of super-large transformers, long-term continuous operation and precise docking installation. Although the initial investment is high, in the long run, it can bring about significant cost savings and efficiency improvements.

If you are looking for a reliable transformer transportation solution, especially for ultra-large transformer transportation needs, please contact us immediately. Our professional team will provide you with customized heavy-duty agv solutions according to your specific needs, including detailed technical parameters, quotation and implementation plan. Let us help you to improve transportation efficiency, reduce costs and ensure the safety of transformer transportation. Click on the “Contact Us” button below to get a free consultation and solution design service!