Key Takeaways: Heavy duty AGVs (Automated Guided Vehicles) address core material handling pain points in the commercial vehicle industry, including low efficiency and high safety risks of traditional methods. They cover the whole life cycle from the storage of parts to the delivery of finished vehicle. Choosing a suitable AGV robot needs to match the load capacity with the component weight, adapt to indoor/outdoor environment and ensure the system compatibility. Longyu AGV System Company provides customized multi-mode navigation and multi-level security protection solutions. Their adoption reduces component damage rates to below 0.05% (Robotics Industries Association, 2024).

What Is a Heavy Duty AGV?

A heavy AGV is an automatic guided vehicle, specially designed for transporting oversized and overweight parts or finished products, and its load capacities is usually more than 10 tons to 300 tons. Different from standard AGV, heavy-duty vehicles integrate high-strength structural design, accurate navigation systems and stable driving mechanisms to adapt to the harsh and complicated environment of commercial vehicle production and storage. It mainly solves the pain points of B 2B in the commercial vehicle industry, such as low coordination efficiency of manually driven forklifts and cranes, high safety risks of heavy parts transfer, poor adaptability to flexible production lines, and difficulty in synchronizing logistics with production plans.

According to the load capacity, heavy duty AGV can be divided into three categories: light-medium (10-50 tons), heavy (50-150 tons) and ultra-heavy (more than 150 tons). Light-medium-sized models are suitable for transporting small and medium-sized components, such as engines and gearboxes; Heavy-duty vehicles are used for core assemblies, such as truck chassis and bus bodies; Ultra-heavy models usually run in multi-vehicle linkage mode, handle ultra-heavy loads, just like finished products of heavy special vehicles.

Why heavy AGV is so important in commercial vehicle industry?

The commercial vehicle industry, including heavy duty trucks, light trucks, buses and special vehicles, relies heavily on the transportation of heavy parts during the whole production and storage process. Traditional transfer methods relies on the cooperation of cranes, forklifts and manual labor, which is difficult to meet the needs of modern intelligent manufacturing. If there is no heavy AGV solutions, enterprises will face three major risks: first, low transfer efficiency leading to the bottleneck of production line, because manual operations is slow and easy to delay; Second, there are high security risks, including collision, component damage, and even personal injuries due to human error; Third, poor compatibility with flexible production, making it difficult to adapt to the production needs of multiple vehicle models and small-batch customization.

The core advantage of adopting heavy AGV systems is significant. First of all, efficiency is greatly improved: compared with the traditional method, the transfer efficiency of heavy AGV is improved by 40% -50%, and the transfer time of a single component is shortened from 40 minutes to 15 minutes. Secondly, safety is enhanced: the multi-level safety protection system eliminates component damage caused by manual operation errors, reducing the component transfer damage rate to below 0.05% (Robotics Industries Association, 2024). Thirdly, optimize production flexibility: AGV robots supports seamless connection with pulsating flexible production lines, realizes automatic path planning and dynamic obstacle avoidance, and adapts to complicated workshop layouts. Finally, the operating costs is reduced: labor demand is reduced by 30%, the 24/7 continuous operation capacity is adapted to the needs of large-scale mass production, and the overall transfer costs is reduced by 35.

Main specifications

| Load level | Loading Capacity | Core navigation technique | Drive Mechanism | Control System. | Security and guarantee | Environmental adaptation |

| Light-Medium Duty | 10-50 tons (adjustable or double-car linkage. | Laser slams trackless navigation with positioning accuracy of 5 mm. | Polyurethane solid rollers with running noise ≤ 65 dB. | Linkage and remote monitoring of MES system. | Laser obstacle avoidance (0.5-5m), acousto-optic alarm and emergency stop. | Indoor workshops, concrete floors, room temperature. |

| High loading | 50-150 tons (single car or multi-car synchronous. | Laser+inertial integrated navigation with 3 mm accuracy; Outdoor GPS is optional | High strength alloy steel rollers, hydraulic suspension. | Distributed synchronization control and stepless speed regulation. | Laser obstacle avoidance, emergency braking, anti-roll warning. | Indoor/outdoor semi-open areas, with protection grade IP 54, -10℃ ~ 45. |

| Extra-Heavy Duty | More than 150 tons (2-4 vehicle linked together, with a maximum of 300 tons. | Laser slam+ visual navigation fusion, 2mm accuracy. | Giant engineering rubber rollers (diameter ≥ 500 mm), multi-wheel distribution. | Industrial 5 g+WiFi dual-mode communication, data real-time interaction. | 360 laser Obstacle Avoidance, Ground Load Detection, Remote Emergency Control. | Outdoor finished product storage yards, the transmission distance is ≤ 1000m, and it is dusty. |

Common Applications of Heavy Duty AGVs

Part warehousing and transfer

This application focuses on the accurate transportation of core heavy components (such as engines, gearboxes and axles) from automated warehouses to production lines. Heavy AGV replaces the traditional forklift truck for round-trip transportation, which realizes the seamless connection between warehouse exit and production line buffer zone. The integration with WMS systems ensures just-in-time material delivery, avoiding material backlogs or shortages.

Transfer of workshop sites

It includes the inter-station transfer of large components, such as body assemblies, chassis assemblies and cabs. AGV robots(e.g.,150 ton Heavy duty AGV) adapt to the connection needs of commercial vehicle pulsating and flexible production lines, especially in the docking and transfer of body and chassis assembly. Their high positioning accuracy ensures accurate assembly docking, thus improving assembly efficiency and quality.

Finished vehicle inspection transfer

Heavy duty AGVs carry finished commercial vehicles to complete multiple post-offline links such as rain tests, performance testing, and exhaust gas testing without manual driving or traction. This application ensures the continuity and stability of the inspection process, avoiding damage to finished vehicles caused by manual operation and improving inspection efficiency.

Finished product warehousing and warehousing

Qualified finished cars are transferred from the inspection area to the finished goods yard, or to the loading area for outbound transportation according to order requirements. Automated guided vehicles realize the automatic connection between warehousing and logistics, and support 24/7 continuous operation. This meets the large-scale outbound demand of commercial vehicle companies and improves the efficiency of order fulfillment.

How to Choose the Right Heavy Duty AGV: Step – by – Step

Step 1: Clarify the Requirements

First, determine the weight and size of the components to be transferred, as well as the specific transfer scenario (indoor/outdoor, workshop/warehousing). For example, transferring engines (2-5 tons) is suitable for light and medium AGV, while transferring heavy truck chassis (50-80 tons) requires heavy vehicles. Make clear the daily transfer quantity and distance to ensure that the selected AGV meets production requirements.

Step 2: Confirm the parameters

Verify key parameters such as load capacity, navigation accuracy and running speed. Ensure that the load capacity matches the weight of components, and avoid “overcapacity” or “insufficient capacity”. For indoor workshops with complicated layouts, laser SLAM navigation with high positioning accuracy is preferred; Outdoor long-distance transfer, choose models with GPS navigation and IP 54+ protection level to adapt to harsh environment.

Step 3: Match the criteria

Check whether the heavy AGV system is compatible with the existing enterprise information systems, such as MES, WMS, ERP, etc. Ensure the consistency of communication protocol and realize seamless data docking, including automatic order release, real-time tracking of transit tasks, and remote monitoring of equipment state. At the same time, confirm that the AGV conforms to industrial safety and quality standards.

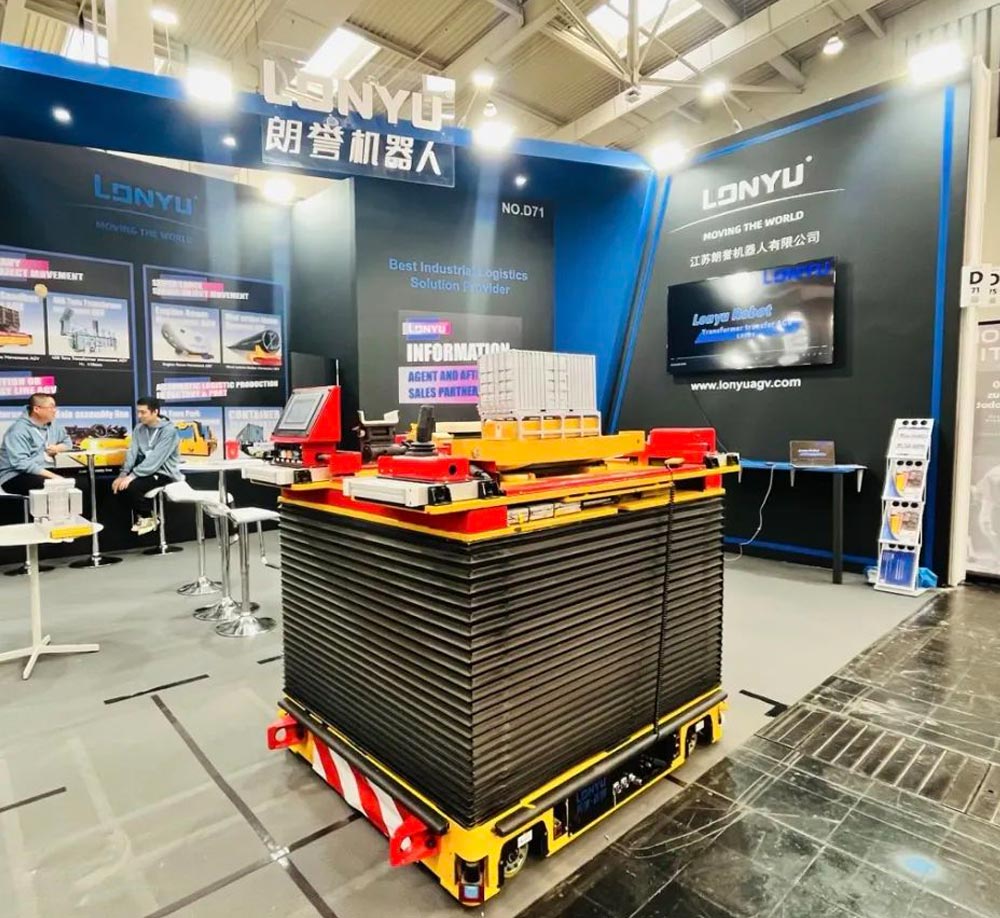

Step 4: Validate the Suppliers

Evaluate the technical strength, project experience and after-sales service of suppliers. Preference is given to suppliers with rich cases in the commercial vehicle industry, such as Longyu AGV System Company, which has professional ability to customize heavy AGV solutions. Verify the supplier’s maintenance support system to ensure timely technical support and spare parts supply during later operation.

Standards, Certification and Compliance

Industry Standards

Heavy duty AGVs for commercial vehicle applications must comply with international and industry standards, including ISO 3691-4 (Safety standard for industrial trucks – Part 4: Automated guided vehicles), GB/t 26949.4-2011 (industrial electric vehicles – Safety requirements – Part 4: Automated guided vehicles), and GB 10055-2021 (Safety code for construction and installation of hoisting machinery). These standards stipulate the requirements for the structural design, safety protection and operational performance of AGV.

Testing Methods

The main test items include load capacity test (verifying the maximum load capacity through static and dynamic load tests), navigation accuracy test (measuring positioning error with laser positioning detectors), safety performance test (testing the effectiveness of obstacle avoidance, emergency braking and alarm systems) and environmental adaptability test (evaluating the operation under high/low temperature, dusty and wet conditions). Recommend a third-party testing institution recognized by CNAS or ILAC to provide objective and authoritative testing results.

Certification guide

Qualified heavy duty AGV products should obtain relevant certifications, such as CE certification (for entry into the European market), FCC certification (for the US market), and CCC certification (mandatory for the Chinese market). In addition, system integration certifications related to intelligent manufacturing, such as ISO 9001 quality management system certification and ISO 45001 occupational health and safety management system certification, is an important symbol of the strength of suppliers.

Who Should Consider Heavy Duty AGV Solutions?

Suitable Companies

The heavy duty AGV solutions is an ideal choice for commercial vehicle manufacturers (including heavy truck, light truck, bus and special vehicle manufacturers) with large-scale production lines; Auto parts manufacturers specialize in heavy components like engines and chassis; Logistics warehousing enterprises undertake the transfer of parts or finished product of commercial vehicles. They are also suitable for enterprises upgrading to intelligent manufacturing and requiring flexible connection between production lines and warehousing systems.

Inappropriate occasions

It is not recommended for enterprises with small production scales and low daily transshipment (less than 50 tons/day) to adopt the solution, because the initial investment cost may not be cost-effective; Enterprises with extremely harsh working environment (e.g., High temperature exceeding 60℃, strong corrosion or uneven ground with errors exceeding 10 mm) exceeds the environmental adaptability of AGV; And enterprises with short production cycles (below 2 years) and no long-term intelligent upgrade plans.

Frequently asked Questions (FAQs)

Q 1: what is the service life of a heavy AGV?

A 1: Under normal operation and regular maintenance, the service life is generally 8-12 years. The service life of core components such as driving system and navigation sensor is 5-8 years, and the overall service life of the AGV can be prolonged by replacing these components.

Q 2: Can heavy AGV work outdoors in rainy environment?

A 2: Yes, heavy duty AGV with protection level of IP 54 or higher can operate in light to moderate rainfall. They are equipped with waterproof and moisture-proof designs for key components like motors and control systems, but prolonged heavy rain or flooding should be avoided.

Q 3: How long will it take to install and debug heavy AGV system?

A 3: the installation and debugging cycle depends on the age of the machine and the complexity of the system. It takes 2-4 weeks for a light and medium AGV; For a multi-vehicle linkage heavy-duty system, it takes 4-8 weeks, including site mapping, path planning, system integration testing, etc.

Q 4: Can heavy AGV be upgraded or modified in the future?

A 4: Yes, Longyu AGV systems adopts modular designs, which supports the later upgrade of navigation systems (for example, Increase visual navigation) and expand load capacity (for example, Converting single-vehicle to multi-vehicle linkage). Software systems can be updated on line to add new functions.

Q 5: What is the energy consumption of a heavy duty AGV, and how is it charged?

A 5: the energy consumption varies with the load and speed; An AGV weighing 50 tons consumes about 20-30 kWh per hour. Charging methods include manual plug-in charging, automatic charging stations and opportunity charging (idle time charging). It takes 2-4 hours to fully charge, and it supports 8-12 hours of continuous operation.

Conclusion

Heavy duty AGV plays a key role in changing the material handling of commercial vehicle industry, and solves the problems of inefficiencies, safety risks and inflexibility of traditional transportation methods. By covering the whole life cycle from component warehousing to finished vehicle warehousing, these automatic guided vehicles improve production efficiency, improve operational safety and optimize production flexibility. The key to a successful application is to choose the appropriate AGV according to the load capacity, scene requirements and system compatibility.

As the development of commercial vehicle industry towards intelligence and customization, the demand for heavy AGV solutions will continue to grow. Choosing a professional supplier with industry experience, like Lonyu AGV Systems, ensures access to customized, reliable solutions that align with long-term development goals. The adoption of heavy duty AGVs is not just a technological upgrade but a strategic investment in improving core competitiveness in the intelligent manufacturing era.