Key Takeaways: the wind power industry faces tough challenges in transferring oversized and ultra-heavy components. Heavy AGV provides a reliable automation solution covering the whole process from production to installation. It is applicable to blade, nacelle, chassis and other component transfers, with three core custom solutions matching different load levels. Four key steps should be followed when selecting (defining requirements, confirming parameters, matching standards, and verifying suppliers). Data show that heavy duty AGV can improve transmission efficiency by 50% and reduce the damage rate of components to zero. For reliable solutions, it is essential to cooperate with a professional agv supplier.

What is the heavy AGV in wind power industry?

A heavy duty AGV (Automated Guided Vehicle) is a type of automated material handling equipment specifically designed to carry ultra-heavy and oversized loads, typically ranging from 10 tons to 400 tons or more. It integrates advanced navigation, synchronous control and safety protection technologies, and realizes the independent, accurate and efficient transfer of goods without manual driving. In the wind power industry, it is mainly used to solve the B2B pain points of low efficiency, high safety risks and easy damage of wind power core components such as blades, engine rooms and wheels by traditional means (crane+manual cooperation).

Industry standard/common name: in the global industrial field, it is generally called “heavy automatic guided vehicle” or “heavy AGV”, and in the wind power industry, it is also commonly called “AGV for wind power component” according to its application scenarios.

Why is heavy AGV so important in wind power industry?

Solving core problems: the wind power industry’s core components (such as blades over 80 meters long and nacelles over 50 tons) have the characteristics of large size, heavy weight and irregular shape, leading to difficulties in transport. Traditional transfer mode relies on the cooperation of crane and manpower, which is prone to problems such as low transfer efficiency, difficult accurate positioning and easy collision and damage to parts. Heavy AGV realizes automatic and accurate transfer, which effectively solving these pain points.

Risks of non-use: According to data from the Global Wind Energy Council (GWEC, https://gwec.net/) , the average loss caused by component damage accounts for 3.2% of the total component cost in the process of transferring wind power components using traditional methods. At the same time, manual operation and coordination mistakes may lead to safety accidents, and the accident rate reaching 0.8% every 100 transfers. In addition, the traditional transfer mode is inefficient, which will delay the progress of production and installation, affecting the time of on-grid power generation of wind farms, and causing economic losses.

Core benefits after use: the application of heavy duty AGV can significantly improve transfer efficiency-data from the International Federation of Robotics (IFR, https://ifr.org/) show that the transfer efficiency of wind power components can be increased by 50% on average compared with the traditional method. It can also reduce the damage rate of parts to zero, reduce the labor demand by more than 35%, and improve the security and stability of the whole transfer process. In addition, the intelligent management function of agv robots helps enterprises to realize digital management of transshipment process.

Main specifications

| Load Level | Adapting parts | Core technical parameters | Key characteristics | Application environment |

| 20-60 tonnes | Wind turbine blades (length greater than 80, weight ≥ 20t. | Dual/multi-vehicle synchronous control (error < 5 mm); Laser positioning+vision scanning (docking accuracy 5 mm); Mecanum wheels 360 ° omni-directional movement; High elastic polyurethane road rollers (single wheel load ≥ 500 kg. | Small turning radius (≤ 3 m); Suitable for narrow passages; Anti-slip roll surface | Indoor workshop, outdoor yard, stone road, concrete floor. |

| 50-400 tonnes | Engine room (50-400 tons), wheel hub (80 tons. | Q 345B+ high strength steel; Shock absorption of intelligent hydraulic suspension; Temperature resistance: -30℃ ~ 80℃; 5 g remote control+digital double visualization. | Strong load-bearing capacity; Multiple security; Weather resistance; Remote supervision. | Indoor production line, outdoor wind farm, rain and snow weather. |

| 10-50 tonnes | Case, fairing | Laser slam navigation; Lateral movement and obstacle avoidance of narrow channel; Modular design; Connected to the pulsating production line. | Flexible in action; The space utilization rate is high; Delivery on time; Easy custom made | Supporting indoor workshop and production line. |

Common application of heavy AGV in wind power industry

Wind turbine blade manufacturing and installation industry: heavy AGV is mainly used for long-distance transfer of blades from the workshop to cargo yard and from cargo yard to the installation site. It solves the problem that blades with a length of more than 80 meters and a weight of 20 tons are difficult to transfer. Compared with traditional crane, it can avoid blade collision damage and improve transfer efficiency.

Wind turbine engine room and wheel hub production industry: For 50-400 ton of engine room and 80 ton of wheel hubs, heavy duty AGV has realized the automatic transfer from the production line to the assembly station and from the assembly station to the wind farm hoisting point. Its precise positioning function ensures the accuracy of assembly and hoisting, reducing manual coordination errors.

Wind power chassis and fairing production industry: For 10-50 tons of chassis and faults, modular heavy AGV realizes automatic distribution of multiple sets of products every day. Linked with the workshop pulsating production line, the materials can be delivered on time and the continuity of the production process can be ensured.

Wind Power Component Post-Processing Industry: Agv robots equipped with 5-ton robotic arms are used for automated connection of blade grinding and painting processes. They reduce the intensity of manual labor, avoid the hidden dangers in manual operation and improve the consistency of post-processing quality.

How to Choose the Right Heavy Duty AGV for Wind Power Industry

Step 1: define the requirements. Firstly, determine the type and weight of wind power components to be transferred (such as blades, nacelle, etc.), the transfer distance (short-distance workshop transfer or long-distance yard transfer) and the transfer environment (road conditions such as indoor or outdoor, cement floor or gravel floor).

Step 2: Determine parameters. According to the clear demand, the key parameters of the heavy duty AGV are determined, including load level, positioning accuracy, moving speed, turning radius, temperature tolerance range and safety protection functions. For example, outdoor transfer needs to confirm the weathering resistance of the AGV.

Step 3: Match criteria. Ensure that the selected heavy AGV meets the relevant industry standards of the wind power industry, such as load-bearing safety standards, navigation accuracy standards, environmental adaptability standards and so on. At the same time, it should be matched with the existing production technology and equipment of the enterprise.

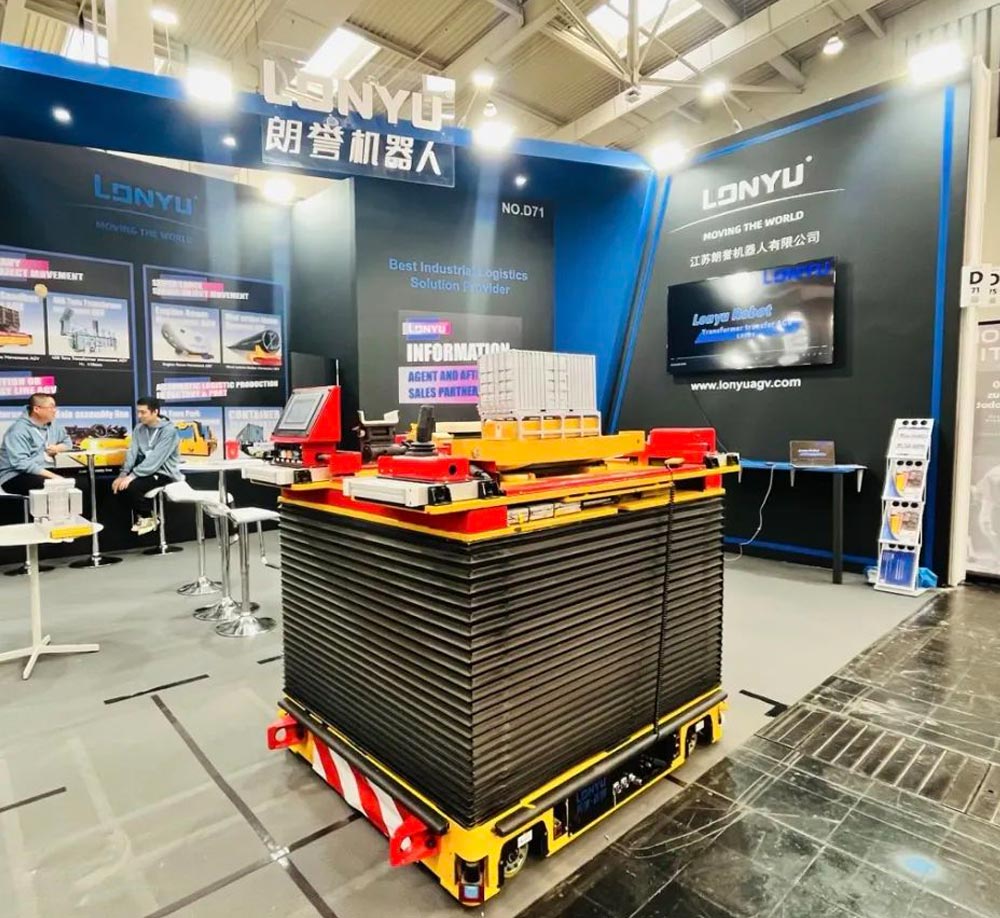

Step 4: verify the suppliers. Select a professional and reliable agv supplier. Verify the technical strength, project experience, after-sales service system and product certification of suppliers in wind power industry. It is suggested that the supplier’s production base and existing customer cases should be inspected on site.

Standards, certification and compliance

Industry standards: Comply with the international standard ISO 3691-4 (Safety requirements for industrial trucks – Part 4: Automated guided vehicles) and the Chinese standard GB/t 26944.4-2011 (industrial trucks – Safety requirements – Part 4: Automated guided vehicles). In the wind power industry, it is also necessary to meet the relevant load-bearing and safety standards for the transfer of wind power component.

Testing methods: the performance testing of heavy duty AGV includes load-bearing capacity testing (using professional load testing equipment), positioning accuracy testing (using laser positioning testing instruments), safety protection function testing (simulating obstacle avoidance and emergency stop scenarios) and environmental adaptability testing (testing in high and low temperature, rainy and snowy environments).

Certification Description: the product should obtain CE certification (for the European market), FCC certification (for the North American market) and industrial product production license in China. At the same time, the product quality and safety should be ensured through the type test of professional third-party testing institution.

Who Should Consider Heavy Duty AGV Solutions?

It is suitable for: wind power component manufacturers (blade, nacelles, wheels and chassis manufacturers), wind farm construction and installation enterprises, and wind power component post-processing enterprises that need to transfer heavy and oversized components and want to improve transfer efficiency, reduce safety risks and realize automatic management.

Not suitable for: Enterprises with small-scale production, light component weight (less than 10 tons) and simple transfer environment, where traditional transfer equipment can meet the needs and the cost of introducing heavy-duty AGV is too high.

Our advantages: As a professional AGV supplier, we have rich experience in customizing heavy-duty AGV solutions for the wind power industry. We can provide personalized equipment configuration and technical support according to the actual needs of enterprises, and have a sound after-sales service system to ensure the stable operation of equipment.

Frequently asked Questions (FAQs)

Q 1: Can heavy AGV adapt to the outdoor complex environment of wind farms?

A 1:That’s right. The 50-400-ton heavy AGV of nacelle and hubs is designed with weatherability, and the temperature range is -30℃ ~ 80℃. It can operate normally in rain and snow, and has the ability to adapt to complex terrains such as gravel and grassland.

Q 2: What is the synchronization accuracy of dual/multi-vehicle linkage heavy AGV used for blade transfer?

A 2: the dual/multi-vehicle synchronization control system ensures that the synchronization error of the heavy duty AGV group is less than ± 5 mm, and the laser positioning+visual scanning technology realizes precise docking with the installation station, with a docking accuracy of ± 5 mm.

Q 3: how to maintain the heavy AGV in the wind power industry?

A 3: Daily maintenance includes cleaning up the sediment on the drum; Quarterly maintenance includes checking the drum wear and replacing it in time when the wear exceeds 10%; It is forbidden to use grease lubricants, so as to avoid polluting wind power components. The supplier usually provide maintenance instructions on a regular basis.

Q 4: Can heavy AGV be customized according to different wind power components?

A 4: That’s right. A professional agv supplier can provide customized solutions according to the weight, size and transfer requirements of different parts. For example, blade transfer adopts a multi-vehicle linkage scheme and chassis transfer adopts a modular backpack scheme.

Summary

In the wind power industry, the transfer of oversized and ultra-heavy components is a key link affecting production efficiency and safety. Heavy AGV provides an effective automation solution, which can cover the whole transportation process from production to installation of wind power generation components. Different load levels of heavy-duty AGV match different transmission requirements of component, and the customized solutions can adapt to various complex environments. When choosing heavy duty AGV, enterprises should follow the four steps: defining requirements, determining parameters, matching standards and verifying suppliers, and choose a reliable AGV supplier to ensure the applicability and stability of the solution. With the continuous development of the wind power industry, the application of agv robots will be more and more extensive, helping the industry to achieve high-quality development.