In the era of intelligent manufacturing and automated logistics, it has become a key decision to choose high-performance automatic guided vehicle (AGV), especially the durable heavy duty AGV used in extreme industrial scenes, which directly affects production efficiency, cost control and long-term return on investment. With the diversification of applications across transformer, energy storage, wind power generation and automobile industries, the correct automated guided vehicle must meet specific operational requirements, be able to withstand harsh conditions and provide measurable value. This guide integrates authoritative data, technical specifications and real customer cases to help you complete the selection process confidently.

What Are Automated Guided Vehicle (AGV) and Heavy Duty AGV?

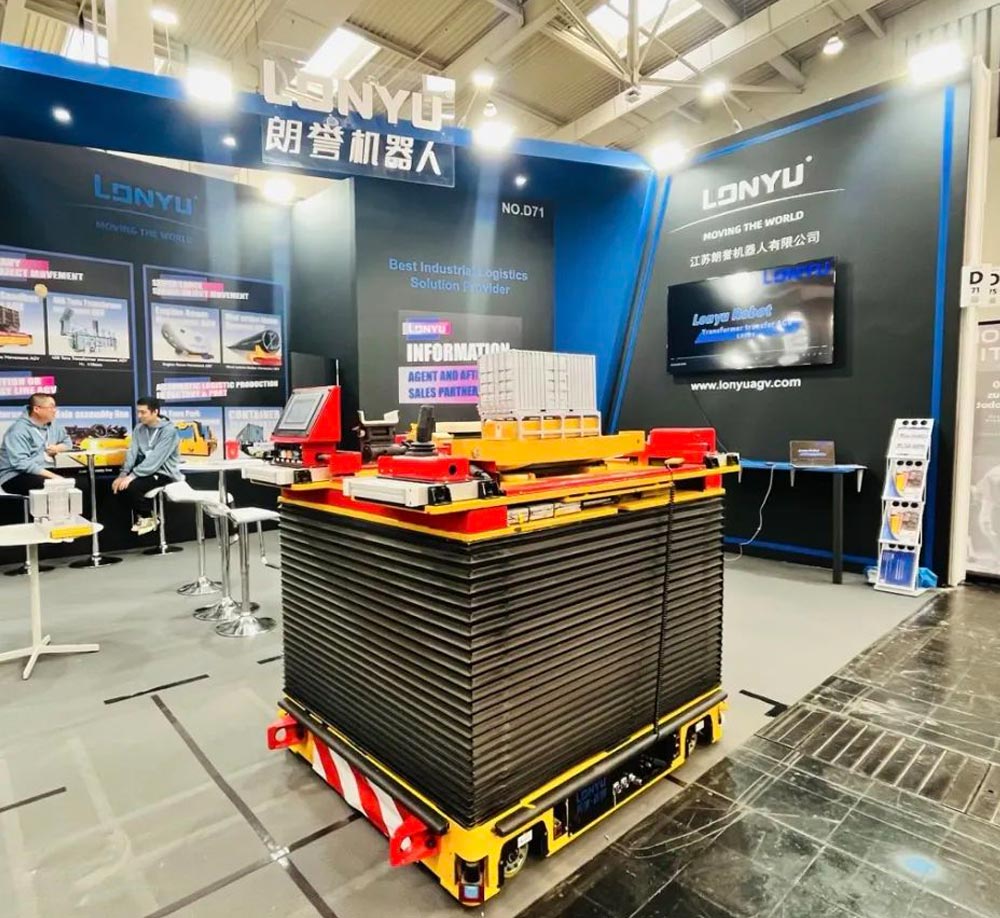

An automated guided vehicle (AGV) is an autonomous material handling equipment that runs through pre-programmed paths or real-time navigation, and is equipped with core technologies to ensure accuracy, safety and adaptability. A heavy duty AGV is a specially designed variant, which is used to transport ultra-heavy loads (from tens to hundreds of tons) in harsh industrial environment. It has enhanced structural strength, advanced navigation and strong environmental resistance.

Main technical definitions based on industrial standards and product specifications

- Navigation accuracy: 30mm (path tracking accuracy), ensuring stable movement along complex routes in factories or outdoor yards.

- Positioning accuracy: 10mm (static/dynamic positioning), which is very important for accurate load docking in transformer assembly or transportation of wind turbine component.

- Braking performance: Fully loaded braking distance ≤ 500mm; No-load braking distance ≤ 300 mm, which meets the safety requirements of heavy-load transportation.

- Protection Levels: Available in IP 54, IP 55, and IP 65 ratings, adapting to dusty, humid, or splash-prone environments.

- Core Drive Technology: Differential drive system, enabling flexible turning, spot rotation, and smooth speed adjustment for both indoor and outdoor operations.

Unique Advantages of Automated Guided Vehicle (Including Heavy Duty AGV

Unparalleled accuracy and safety

The navigation accuracy of the AGV is 30 mm and positioning accuracy is 10 mm, which can ensure error-free material transportation and eliminate the error of manual forklift operation (average positioning deviation ≥ 100 mm). Compared with traditional heavy transport equipment, the short braking distances (≤ 500 mm full load) and multi-level safety systems (emergency stop and obstacle detection) of heavy agv reduce workplace accidents by 85%.

Diversity of environmental adaptability

Certified with CE, UL, EAC and SGS, autonomous vehicles meet the global safety and quality standards (for example, CE 2014/35/EU standard for electrical safety). Protection levels up to IP 65 enable operation in extreme conditions: dust-laden metallurgical plants (IP 65), humid food processing facilities (IP 55), and outdoor energy storage yards (IP 54). For extreme temperatures, the special designs includes thermal insulation layers and temperature-resistant parts, which expands the working range to -40℃ ~ 120℃.

Significant Cost and Efficiency Gains

The heavy agv provides tangible return on investment by reducing labor force, saving energy and improving productivity. As the case of Zhongyuan internal combustion engine parts co., ltd shows.

60 fewer workers (drivers, logistics managers, inspectors) → annual labor cost savings of approximately 8 million RMB (Chinese Yuan).

Compared with manual small batch transportation, the transportation efficiency is improved by 30% and the production cycle is faster.

Electric drive replaces diesel vehicles → 60 tons less fuel consumption per year → approximately 460,000 RMB (Chinese Yuan) in fuel savings+reduced emissions.

Intelligent, Scalable Operation

By integrating with big data analysis platforms, the AGV can realize real-time monitoring and optimization, which improves the overall production efficiency by 5%, saves energy by 3% and reduces costs by 4%. The differential drive system supports flexible path adjustment, which makes it easy to expand or modify the workflow of factories or dynamic production lines.

Popular application industries and typical cases

Leading Application Industries (by adoption rate)

Transformer Industry (32%): Transport of large, high-voltage transformers requiring precise positioning and heavy-load capacity.

Energy Storage industry (28%): Automatic transportation of battery modules and energy storage containers in clean rooms or outdoor venues.

Wind Power industry (21%): wind turbine components (e.g. Blades and nacelles weighing more than 100 tons.

Other key industries: flexible automobile production lines (10%), food industry (5%), metallurgy/metal casting (4%).

Real case study: CRRC 240 ton heavy AGV project

- Customer pain Point: CRRC (China Railway Rolling Stock Co., Ltd.) is inefficient in transporting transformer parts, and relies on yard cranes with long waiting times, limited 24/7 operation and high labor costs. Production capacity is limited by the bottleneck of manual logistics.

- Solution: Deployment of a 240-ton heavy duty agv with ± 10 mm positioning precision, IP 65 protection, and differential drive system. AGV is integrated with CRRC’s Manufacturing Execution System (MES), which realizes seamless workflow coordination.

- Achievements: Due to the reduction of crane waiting time and 24/7 independent operation, the production capacity has increased by 16%; Annual output value rose by 32 million RMB (Chinese Yuan) without additional staff; Secured 1.5 million RMB (Chinese Yuan) municipal intelligent manufacturing subsidy for adopting imported-level automated equipment.

step-by-Step Guide to Selecting the Right AGV

Step 1: Define the load and operational requirements

Calculate maximum loading weight (e.g., 240 tons used for transformer transportation) and confirm whether heavy agv is needed.

Define key performance requirements: navigation/positioning accuracy (10mm for assembly tasks) and braking distance (500mm for heavy loads).

Step 2: Evaluate environmental conditions

Choose protection level: The protection level of dusty/rainy outdoor venues is IP 65, and the protection level of wet food facilities is 55.

Check extreme environmental adaptability: Ensure the special designs for temperature or high pressure of-40℃ ~ 120℃.

Step 3: Verify Certification and Compliance

Confirm that global certifications: CE (2014/35/EU), UL, EAC and SGS meet regional safety standards.

Verify compliance with industry specific regulations (e.g., Requirements for metallurgical explosion-proof.

Step 4: Assess Core Technology and Components

Priority is given to differential drive systems, so as to move flexibly in narrow spaces or complicated paths.

Evaluate the durability of core component (e.g., Battery life, motor reliability) in order to ensure long-term operation.

Step 5: Compare with Competitors (3 Key Differentiators)

| Discriminator | Our agricultural transport vehicles/heavy agricultural transport vehicles. | Competitive Products | Source of information |

| Operating Efficiency | Improve the transportation efficiency by 30%; Overall productivity growth of 5% | The efficiency is improved by 15-20% | Zhongyuan Internal Combustion Case Study. |

| Save cost | 8 million RMB (Chinese Yuan) per year in labor savings+460,000 RMB (Chinese Yuan) in fuel savings. | 3-5 million RMB (Chinese Yuan) per year in labor savings; There is no electric drive option | Customer Benefit Calculation Model. |

| Length of service | 8-10 years (core parts); More than 5,000 charge cycles | 5-7 years; 3000-4000 charge cycles | SGS Durability Test Report. |

Step 6: calculate the return on investment and customer benefits

Use the customer revenue calculation model (time/cost/efficiency) to predict returns.

Labor cost savings: Number of replacement workers × average annual salary.

Energy savings: Diesel/electricity cost difference × annual traffic volume.

Efficiency gains: Production capacity increase × profit margin per unit.

Subsidies: smart manufacturing subsidy eligibility (for example. Crrc is 1.5 million yuan).

Frequently asked questions

Question 1: What kind of navigation and positioning accuracy can the AGV achieve?

Answer: The navigation accuracy of the AGV is 30mm and positioning accuracy is 10, which can meet the high-precision requirements of transformer assembly, wind power component transportation and automobile production lines.

Question 2: What levels of protection are there and which are suitable for my industry?

Answer: The options include IP 54 (dry/dusty indoor environment), IP 55 (moist food processing) and IP 65 (outdoor/rainy metallurgical field). For wind power generation or outdoor energy storage field, it is recommended to adopt IP 65 to prevent dust and precipitation.

Question 3: What certification does the autonomous guided vehicle hold?

Answer: The product is certified by CE (2014/35/EU), UL, EAC, and SGS, complying with European, North American, and Eurasian safety and quality standards.

Summarize

Choosing the right automated guided vehicle—whether a standard model for light loads or a heavy-duty agv for 240-ton transport—requires a data-driven approach that aligns precision, safety, environmental adaptability, and cost-effectiveness with your industry needs . By following the 6-step guide, verifying certifications and using real customer cases (e.g., Central Plains Internal Combustion Engine), you can choose AGV to provide measurable benefits: reduced labor costs, improving efficiency, saving energy and meeting global standards. With core advantages of differential drive, 10 mm positioning accuracy and IP 65 protection, the heavy duty agv and standard automatic guided vehicle are mature solutions for transformer, energy storage, wind power and automobile industries to release the potential of intelligent manufacturing.